We are standing at the threshold of the biggest business opportunity in a century. Despite conventional wisdom that adding 2.5 billion people to the planet will result in stagnating economic growth, extreme resource depletion, accelerating commodity price inflation, and increasing pollution, we contend that, instead, we confront an opportunity that will reframe the world’s economy and create opportunities for trillions of dollars in profits.

The next industrial revolution has, in fact, already begun, and it will dwarf the previous industrial revolutions in both size and speed. Managing businesses in this revolution will be hard. Revolutions are always hard. But managers who can adopt the necessary new methods will achieve breakthroughs in efficient use of resources, seize tomorrow’s biggest growth opportunities, and create the companies that lead the global economy for the next century.

The principles of this next industrial revolution are still a work in progress. They have to be. No one can predict how business will look in twenty or thirty years, any more than Watt could have foreseen how his steam engine would transform the world. But we’ve already seen enough success that we can say, with confidence, both that resources are the right area of focus and that the opportunities are extraordinary. We also have identified five principles that can be applied to make any company, any supplier community, and any customer segment drastically more efficient in using resources, making resource productivity sustainable. In this article, we will share one of these key principles—substitution—and explain how it will lead to far different products and services—those that deliver more performance with fewer resources.

The guiding principle for substitution: Look at every single resource a company uses in its core products and every single resource that customers use or consume, then look for higher-performing, less expensive, or less scarce materials that might work as substitutes. But don’t think of the new resources as straight substitutes for the current bill of materials. Look at how substitutes can deliver superior overall performance—carbon fiber will not only save some weight but will let a company build a better car or airplane.

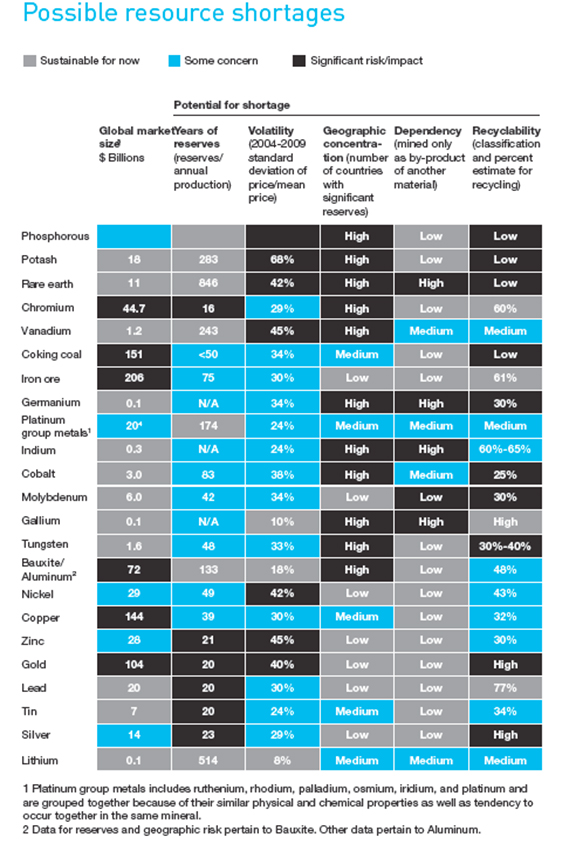

They have developed substitution opportunities for each risky element. We recently completed a review for a major oil company looking at the resource risk embedded in its supply chain and found that lack of available water looked likely to cut its growth sharply below expectations over the next decade. Looking a decade ahead gives companies a time advantage in responding to potential constraints.

A much richer understanding of materials science at the nanometer scale combined with advanced computer processing power has catalyzed a broad revolution in surface properties, absorption characteristics, and optical and electrical properties. Activated carbon, typically made of nanoscale particles with custom-engineered pore size—is dramatically improving the efficiency of water filters, electrodes in batteries, and, potentially, even power-plant exhaust scrubbers. For the first time since the development of leaded crystal centuries ago, glass is being reinvented—from high-bandwidth optical networking fiber to Gorilla glass that Corning has developed to allow touch screens to capture the imagination in portable devices and, soon, on larger interactive screens. A company called View is even creating something it calls “dynamic glass,” which can change its visible and infrared light transmission, enabling windows that can be programmed to block the sun on hot days but capture sunlight in the depth of winter, replacing heating and air-conditioning in Mediterranean climates where cool nights mix with hot days.

Another form of substitution is inspired by biology. Swiss engineer George de Mestral in 1941 invented the Velcro fastener when he decided to take a closer look at burrs he removed from his dog to see how they worked. Dermal denticles that mimic shark skin have produced quieter submarines and faster swimsuits. Inspired by the structure of the lotus flower, a German company, Ispo, has developed a paint that rejects dirt.

Challenges

In the Iraqi war, heavy steel plates in body armor have been replaced by ceramic composite plates that are lighter, more mobile, and stronger, like the shells of crustaceans—reducing fatalities despite the increase in improvised explosive devices. Nature can also inspire changes in production processes themselves, substituting room-temperature, water-based self assembly for energy-intensive smelting processes that operate at high temperature and high pressure. Natural processes are also typically reversible, meaning materials can be recovered or reused.

The potential for substitution extends even to food production. Hampton Creek Foods, for instance, is substituting away from using corn in producing eggs. Some 1.7 trillion hens’ eggs are laid every year, but only about 6 percent are sold in stores. The rest are used to hold mayonnaise together, in baked goods, and to handle other behind-the-scenes tasks. Hampton Creek has developed “plant-based” eggs, a substitute called Beyond Eggs that uses peas, sorghum, beans, and other plants to make a product that tastes like, and has the same nutritional properties as, eggs.

Basically, Hampton Creek thinks it can give us the nutrition directly from plants without having to pass them through a hen. The company says its process is already nearly 20 percent less expensive than the price of making eggs, and costs will fall as scale increases. Hampton Creek also says its product will suffer less from drought—at the moment, about 70 percent of the cost of an egg is corn, a crop that is susceptible to drought and is increasingly linked to the price of oil; Hampton Creek uses hardier crops and relies less on oil. So, Hampton Creek’s egg substitute may offer lower cost and lower risk for major food producers.

Proterra, a manufacturer of buses, shows how substitution can add value across a number of dimensions. Proterra uses a light, carbon-composite body instead of a traditional metal one and substitutes an electric motor and battery for a combustion engine. Like a Prius-style hybrid car, the Proterra bus captures energy from braking and stores it in the battery for reuse, a big gain in stop-and-go city traffic. In all, the Proterra bus is five times more fuel efficient than traditional fossil-fuel buses on city routes. Proterra’s form of substitution—tailoring a product specifically to its application—generates significant savings for companies.

The Proterra bus, like all electric vehicles, also creates an important option. A traditional gasoline-powered bus can only burn gasoline and a diesel vehicle can only burn diesel, but a vehicle powered from electricity can be powered by whatever fuel source is most cost-efficient at the time, whether that’s natural gas, solar, or some other form of energy that generates electricity.

Sometimes, the option to substitute can add just as much value as the substitution itself. Technology that enables easy substitution will keep costs lower and more stable over time.

With permission of Amazon Publishing/New Harvest. ©2014 by Stefan Heck and Matt Rogers. All rights reserved.

SC

MR

Latest Supply Chain News

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- More News

Latest Resources

Explore

Explore

Topics

Latest Supply Chain News

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- More latest news

Latest Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks