Beneficial cargo owners are increasingly focusing on reducing Scope 3 emissions in their supply chains—all members of the worldwide air cargo logistics industry need to respond.

Let’s begin with a definition of emissions. The Scope 3 category is comprised of a company’s indirect greenhouse gas emissions up and down the value chain, including packaging materials and other operations of the supply chains. In other words, the activities of vendors and partners in a supply chain which create greenhouse gas emissions can affect the Tier 1 company’s efforts to achieve their environmental goals. Scope 1 emissions are directly controlled by the emitter, such as wastewater or smoke from a manufacturing plant, while Scope 2 emissions are related to the purchase of energy and heating fuels (footnote i).

Reducing Scope 3 emissions is a part of the ongoing efforts of companies to address environmental issues and to increase their level of sustainability. A sustainable operation can respond quickly to a disruption. Also, it can absorb long-term changes without negatively impacting the company’s ability to provide existing products and services or to develop new products and services at profitable levels.

Most large companies have embraced the commitment to reduce emissions as part of the effort to slow down the warming of the earth’s atmosphere. Companies including Nike, The Estée Lauder Companies, and McCormick & Co. are leaning on their supply chains to reduce emissions. In the case of Nike, the company’s supply chain represents more than 90% of the company’s climate footprint (footnote ii). This is a big target for Nike’s efforts to address sustainability and environmental impacts.

McCormick & Co. is engaging with its suppliers to reduce emissions in part because its customers, including Walmart, are pushing for more sustainable products as they reduce their own Scope 3 emissions (footnote iii).

UPS is employing machine learning algorithms to optimize truck routing thus saving millions of gallons of fuel and reducing emissions.

In addition, a growing number of institutional investors are applying pressure on companies for measurable reductions in environmental impacts. The use of data and information sharing is a vital component to achieving environmentally focused goals.

A recurring theme at a May conference sponsored by The Economist to track and reduce emissions was the employment of data combined with creativity working through supplier partnerships. Marshall Wilmot, president, retail and CDO of ATCO Ltd., has stated that “we have to have a pragmatic and affordable roadmap. It can’t be done while sacrificing key elements like safety, reliability, and affordability that our customers rely on.” (footnote iv) Collaborative efforts are a critical pathway to a successful outcome, not just to achieve high levels of sustainability and reduced emissions, but in all aspects of business.

The commercial aviation industry has devoted significant effort toward the development and use of sustainable aviation fuels (SAF). While these investments are admirable, they do not address the rest of the worldwide air cargo logistics industry. Increasingly, what happens on the ground, i.e., from the manufacturer to the airport, at airports, and then to the final customer. In the case of the air cargo industry, there are numerous opportunities at airports which reduce costs, create new business opportunities, and reduce emissions.

Creating a scalable and realistic plan to increase sustainability and reduce emissions requires a thorough understanding of the entire supply chain. The process should begin by collaboratively formulating goals and objectives for the complete supply chain. The next step is to collect data and information that allows the partners to identify the source, scale, and impact of emissions. The information is then analyzed to identify the root causes of the environmental impacts of the operational elements. With this compiled information, decisions can be formulated to achieve the goals and objectives in a pragmatic way. The decision-making must be conducted in an open and collaborative environment that allows all members to raise issues and arrive at the optimal solution.

An example of the benefits of this approach is addressing the inefficient movement of trucks delivering and collecting cargo at airport terminals. This inefficiency creates excess emissions, negatively affects revenue flows of the trucking companies and terminal operators and adds costs due to the random arrival of trucks. By implementing a platform, such as an airport cargo community system, the movement of trucks at the cargo terminals will be more efficient. The result will be a reduction in emissions, better use of vehicles, terminal capacity, better utilization of employees, and improved service levels for the beneficial cargo owners. In other words, a win-win achievement for everyone.

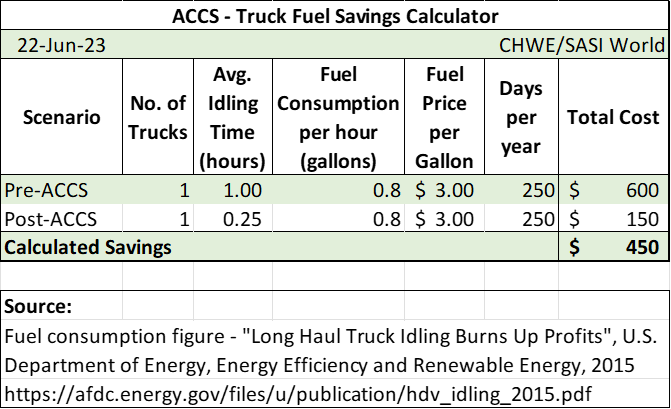

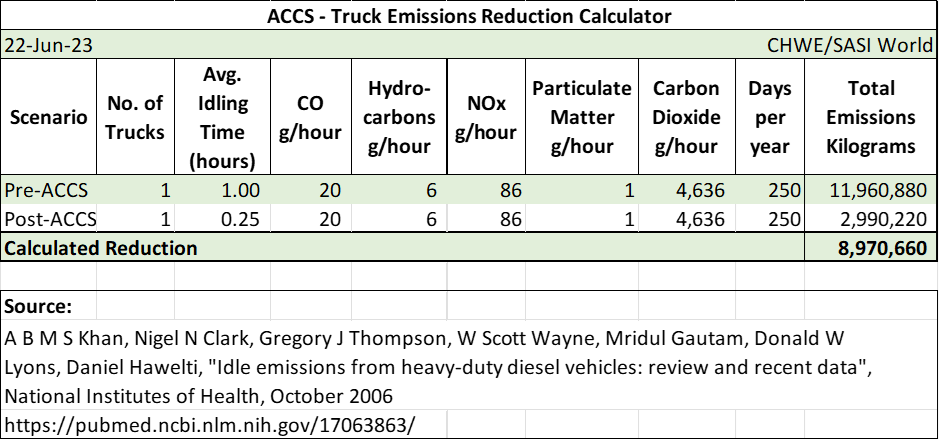

The following tables illustrate the fuel cost savings and reduced emissions by reducing the idling time of one truck from an average of 2 hours to 15 minutes over a year.

The calculated removal of almost 9 million kilograms (9,888 tons) is significant. The health benefits to truck drivers, terminal staff, and others in the immediate vicinity of the idling truck is important as well.

Fashioning a proactive pragmatic program within a collaborative structure that is based on current data and information is the best way to create and sustain sustainable operations that also address Scope 3 emissions. This will meet the expectations of the beneficial cargo owners who are searching for leaders, not laggards, that create collaborative data-based programs that result in long-term sustainable services.

Yes, change is scary…we all like stability. But the worldwide air cargo industry has always been changing, so get on board and become part of a team which is saving money and reducing unhealthy emissions.

About the author:

Charles H.W. Edwards, B.A., M.Sc., MBA, has over 50 years in the transportation, distribution, and logistics industry. Edwards is a vice president of SASI World and a professor of the practice at the University of North Carolina at Chapel Hill in the Department of City and Regional Planning. He is a scholar fellow of Sigma Chi Mu Tau (Supply Chain) honor society. He began his career as a truck driver in Toronto. Since then, Edwards has worked in international freight forwarding in Canada and the UAE, numerous sectors of the airline industry, aviation design and manufacturing in Germany and the United States, ocean freight, rail management, economic development, and logistics education. Edwards can be contacted at [email protected].

Footnotes:

Toplensky, R., “Google Executive Says AI Can Speed Up Climate Action”, The Wall Street Journal”, June 23, 2023, pg. B5

Unglesbee, B., “How Nike, McCormick and others are taking on supply chain emissions”, Supply Chain Dive, June 7, 2023

Toplensky, R., “Google Executive Says AI Can Speed Up Climate Action”, The Wall Street Journal”, June 23, 2023, pg. B5

“In their own words – How CEOs are forging paths to sustainability”, Global C-suite Series, 25th Edition, IBM Institute for Business Value, January 2023

SC

MR

More 3PL

- Orchestration: The Future of Supply Chain

- February and year-to-date U.S. import volume is solid, reports S&P Global Market Intelligence

- 2024 retail sales forecast calls for growth, says National Retail Federation

- ISM reports another month of services sector growth in February

- February manufacturing output declines, notes ISM

- How to Create Real Retailer-Brand Loyalty

- More 3PL

Latest Podcast

Explore

Explore

Business Management News

- Few executives believe their supply chains can respond quickly to disruptions

- Technology’s role in mending supply chain fragility after recent disruptions

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- More Business Management

Latest Business Management Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks