Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

July-August 2018

At Supply Chain Management Review, we’ve been writing about the talent crisis in our profession since at least 2012 when our MIT contributors were publishing a column on talent strategies. Last winter, the topic touched home when I picked up my local newspaper one Saturday morning. One of the lead stories was about two initiatives launched by C&S Wholesale Grocers with two local academic institutions: Keene State College and Franklin Pierce University. Browse this issue archive.Need Help? Contact customer service 847-559-7581 More options

I have been a member of the Manufacturing Leadership Council’s Board of Governors since 2010. Last September the council asked if I would be willing to do a phone interview for research it was conducting for a factories of the future study* sponsored by two of its manufacturing company members: GE and Intel. I agreed. I’m always happy to give an opinion about the future of supply chains since having launched the MIT Supply Chain 2020 Project in 2004, and often think 10 years to 15 years into the future.

The first topic I discussed with the researchers dealt with the future state of factories and plants over the next 10 years: How will they be organized and operated? I told them that my perspective is based on “Small Is Beautiful,” a thought-provoking book by the economist Ernst F. Schumacher that I read more than 40 years ago.**

“Small is Beautiful” for the earth

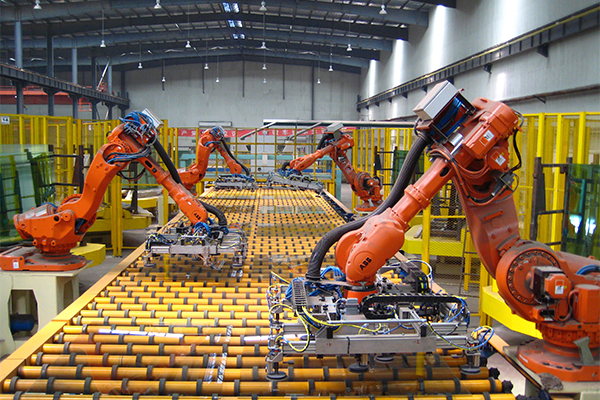

My main takeaway from the book is that the ideal future manufacturing model has to be natural resource efficient. That is one in which goods ought to be sourced and made as close as possible to end-consumers. Back in the day, our “modern manufacturing model” encompassed building large plants to service large swaths of the earth in order to get manufacturing economies of scale. Huge efforts were required to build them and then source them with commodities from distant locations. In addition, the so-called “last-mile” delivery of finished goods to end consumers too often meant the “last thousand miles” or more.

This complete article is available to subscribers only.

Log in now for full access or start your PLUS+ subscription for instant access.

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

July-August 2018

At Supply Chain Management Review, we’ve been writing about the talent crisis in our profession since at least 2012 when our MIT contributors were publishing a column on talent strategies. Last winter, the topic… Browse this issue archive. Access your online digital edition. Download a PDF file of the July-August 2018 issue.SCMR1807_C_InSights.pdf”>  Download Article PDF

Download Article PDF

I have been a member of the Manufacturing Leadership Council's Board of Governors since 2010. Last September the council asked if I would be willing to do a phone interview for research it was conducting for a factories of the future study* sponsored by two of its manufacturing company members: GE and Intel. I agreed. I'm always happy to give an opinion about the future of supply chains since having launched the MIT Supply Chain 2020 Project in 2004, and often think 10 years to 15 years into the future.

The first topic I discussed with the researchers dealt with the future state of factories and plants over the next 10 years: How will they be organized and operated? I told them that my perspective is based on “Small Is Beautiful,” a thought-provoking book by the economist Ernst F. Schumacher that I read more than 40 years ago.**

“Small is Beautiful” for the earth

My main takeaway from the book is that the ideal future manufacturing model has to be natural resource efficient. That is one in which goods ought to be sourced and made as close as possible to end-consumers. Back in the day, our “modern manufacturing model” encompassed building large plants to service large swaths of the earth in order to get manufacturing economies of scale. Huge efforts were required to build them and then source them with commodities from distant locations. In addition, the so-called “last-mile” delivery of finished goods to end consumers too often meant the “last thousand miles” or more.

SCMR1807_C_InSights.pdf”>  SUBSCRIBERS: Click here to download PDF of the full article.

SUBSCRIBERS: Click here to download PDF of the full article.

SC

MR

Latest Supply Chain News

- Technology’s role in mending supply chain fragility after recent disruptions

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- More News

Latest Podcast

Explore

Explore

Software & Technology News

- Technology’s role in mending supply chain fragility after recent disruptions

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- Tips for CIOs to overcome technology talent acquisition troubles

- More Software & Technology

Latest Software & Technology Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks