Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

July-August 2021

We all know the old saying: “When the going gets tough, the tough get going.” It has been repeated so often it’s cliché. I’d like to suggest a variation: “When the going gets tough, leadership matters.” To say that supply chains have had a tough time of it would be an understatement. Despite the positive vaccine news here in the United States, global supply chains are not out of the woods yet. Browse this issue archive.Need Help? Contact customer service 847-559-7581 More options

New and emerging technologies are changing the way supply chains operate. The importance of technology on supply chains continues to increase with the many recent external changes affecting supply chains, such as the pandemic, supply shortages and security threats. Among the technological developments making an impact on supply chain is artificial intelligence (AI), which can help supply chains make more accurate predictions and thus make more informed decisions.

View the related APQC infographic titled “With AI comes the need for Employee Learning”

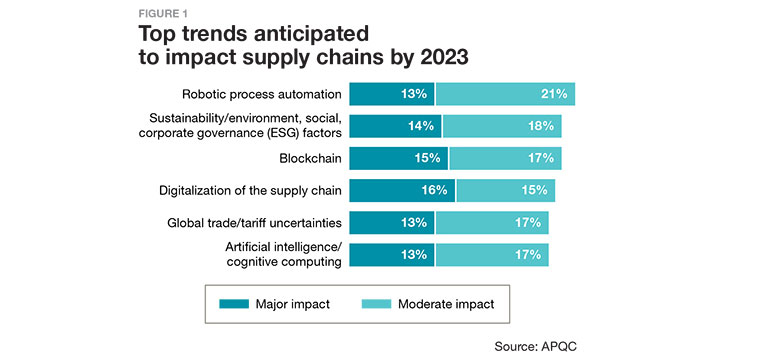

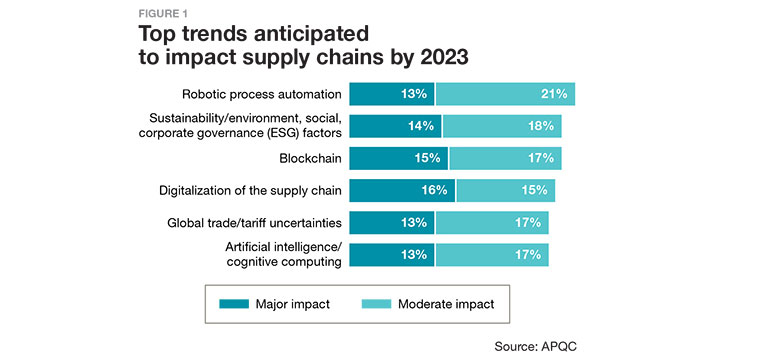

AI has the potential to assist with all aspects of the supply chain, from the ability to create self-adjusting supply chain plans to enabling manufacturing operations to self-optimize processes. In fact, in research conducted by APQC, AI is among the top six trends expected to make a significant impact on supply chains by 2023 (see Figure 1).

With many organizations seeing AI as integral in the future, businesses must consider how this technology will alter their staffing needs and the skills needed by their supply chain employees. After all, with better predictions and recommendations will come the need for employees who can make smart decisions based on that information.

APQC’s research examined the current level of AI adoption among organizations and how the technology is changing the skills required of employees. Smart companies are dedicating time and resources to getting their employees training and development they need for reskilling. This effort is essential to preventing skills shortages as the supply chain field continues to evolve.

AI adoption

Although AI has the potential to make a profound impact on supply chains (and often does among organizations that have fully adopted the technology), its use is not yet widespread. For those using AI, it is still relatively new to their everyday environment. APQC’s research indicates that only 13% of organizations using AI have been doing so for more than two years. A larger number have adopted the technology only recently—36% have had it in place for less than one year. Further, about half have used AI for one year to two years.

Figure 2 shows the degree to which supply chain organizations have adopted AI overall. Almost half of organizations have not yet piloted the technology. Only 38% of organizations have moved beyond the piloting stage. Currently 21% of organizations are still considering the adoption of AI, although this number seems poised to change given AI’s status as a top trend affecting supply chain.

Interestingly, these percentages do not change much when looking at the degree of adoption for specific segments of the supply chain. For logistics and warehousing, only about 39% of organizations have moved beyond the piloting stage of AI technology. This indicates that organizations recognize the wide-ranging applicability of this technology for supply chain use, but it also means that its impact on employee skills is also wide-ranging.

Impact on employees

Many organizations believe that AI drives value through its impact on the number of employees needed for the supply chain. Of the organizations surveyed by APQC, 46% consider a reduction in headcount to be a top driver for deploying AI. A similar amount, 44%, consider headcount redeployment to be a top driver. As AI takes on more tasks previously completed by employees, organizations expect to be able to reduce the number of employees working in supply chain or redirect their skills to other areas.

However, as shown in Figure 3, organizations have not seen much churn in their supply chain employees. At the median, they have only seen a 6% change in the number of full-time equivalent (FTE) supply chain employees over the last 12 months.

Perhaps even more interesting is the fact that, at the median, organizations are actually adding more FTEs as a result of AI than they are eliminating or redeploying. At the 25th and 75th percentiles, there is no difference between the percentage of FTEs added due to AI and the percentage of FTEs eliminated

or redeployed.

This is counterintuitive to the widespread expectation that the use of AI will eliminate the tasks undertaken by some supply chain employees and thereby eliminate the need for these employees altogether. Rather than replacing employees, AI is changing the skills needed by supply chain professionals.

New skills needed

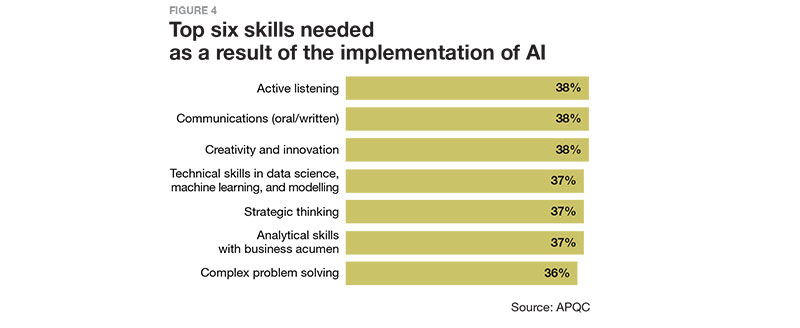

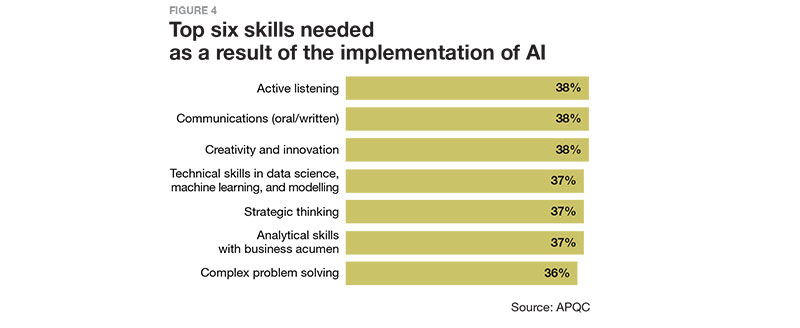

APQC has investigated the shift in skills needed among supply chain professionals. As a result of the adoption of AI, supply chain professionals are taking on tasks that require more social and deep work skills (or those enabling workers to focus intensely without distraction). AI and its resulting automation of tasks leaves the humans on staff to engage in work involving analysis and insight. Technology is no substitute for the relationship-building skills that support listening to stakeholders, communicating effectively with business partners, innovating and thinking strategically about how to approach challenges.

Figure 4 shows the top six skills organizations need their supply chain employees to develop or enhance as a result of the adoption of AI. Most of these are softer skills related to building relationships and

solving complex problems.

Communication and active listening are among the most needed skills. Supply chain employees must be able to discern the needs of their stakeholders and business partners, maintain positive relationships with partners and succinctly and clearly convey expectations to suppliers and other service providers. Creativity and innovation are among the most important skills because of the shifting nature of the modern supply chain. With supply chains forced to address previously unheard-of situations and disruption, such as the global pandemic, professionals must be able to identify novel solutions to keep the business running.

Related to innovation and creativity is the ability to think strategically and solve complex problems. AI can use data to predict any shifts necessary for manufacturing operations and planning. However, the technology should support smart decision making and problem solving by employees. This is where the soft skills of employees become critically important. Supply chain professionals must be able to look at evidence and make the best decision for the business, especially in situations in which there is no evident “right” answer.

Despite the overwhelming need for strategic and relationship-building skills, supply chains still need employees with more technical skill sets, such as in data science and analysis. These skills are necessary to adopt, maintain and support AI within supply chain.

Other skills that more than one-third of research participants want to see employees develop or enhance as a result of the adoption of AI include: complex problem solving, the ability to extract insights from new technology or systems, and agility and flexibility to adapt to change.

Invest in employee learning

As the skills needed by supply chain professionals working with AI continue to change, companies are investing in training and development to help their employees keep up. It is reassuring to see that employees are not being left to fend for themselves when it comes to honing the new skills and capabilities needed. APQC sees that this support is true regardless of industry. At the median, organizations are investing in seven days of employee learning per employee to ease this transition.

Organizations are also adjusting their learning budgets to ensure that their employees get the skills development they need. According to APQC’s research, AI accounts for a 30% change in learning budgets at the median.

Looking forward

The impact of AI on the supply chain will only continue to increase in coming years. With 40% of organizations currently considering or evaluating the use of AI for supply chain, there is a good chance that a company will be adopting it soon if it has not done so already. The key to retaining employees who will thrive in future supply chain roles is to ensure that they have the right mix of skills to support this

technology and leverage it strategically.

Many organizations have already committed to providing learning opportunities for supply chain professionals to develop or enhance critical skills. Although AI does not deliver the reduction in headcount some companies believed would come with it, retraining prevents skills shortages and is a smarter investment than trying to hire new individuals with the necessary skills. APQC encourages organizations to consider employee learning as part of the business case for investing in AI.

About APQC

APQC helps organizations work smarter, faster and with greater confidence. It is the world’s foremost authority in benchmarking, best practices, process and performance improvement, and knowledge management. APQC’s unique structure as a member-based nonprofit makes it a differentiator in the marketplace. APQC partners with more than 500 member organizations worldwide in all industries. With more than 40 years of experience, APQC remains the world’s leader in transforming organizations. Visit us at apqc.org and learn how you can make best practices your practices.

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

July-August 2021

We all know the old saying: “When the going gets tough, the tough get going.” It has been repeated so often it’s cliché. I’d like to suggest a variation: “When the going gets tough, leadership matters.”… Browse this issue archive. Access your online digital edition. Download a PDF file of the July-August 2021 issue.New and emerging technologies are changing the way supply chains operate. The importance of technology on supply chains continues to increase with the many recent external changes affecting supply chains, such as the pandemic, supply shortages and security threats. Among the technological developments making an impact on supply chain is artificial intelligence (AI), which can help supply chains make more accurate predictions and thus make more informed decisions.

View the related APQC infographic titled “With AI comes the need for Employee Learning”

AI has the potential to assist with all aspects of the supply chain, from the ability to create self-adjusting supply chain plans to enabling manufacturing operations to self-optimize processes. In fact, in research conducted by APQC, AI is among the top six trends expected to make a significant impact on supply chains by 2023 (see Figure 1).

With many organizations seeing AI as integral in the future, businesses must consider how this technology will alter their staffing needs and the skills needed by their supply chain employees. After all, with better predictions and recommendations will come the need for employees who can make smart decisions based on that information.

APQC’s research examined the current level of AI adoption among organizations and how the technology is changing the skills required of employees. Smart companies are dedicating time and resources to getting their employees training and development they need for reskilling. This effort is essential to preventing skills shortages as the supply chain field continues to evolve.

AI adoption

Although AI has the potential to make a profound impact on supply chains (and often does among organizations that have fully adopted the technology), its use is not yet widespread. For those using AI, it is still relatively new to their everyday environment. APQC’s research indicates that only 13% of organizations using AI have been doing so for more than two years. A larger number have adopted the technology only recently—36% have had it in place for less than one year. Further, about half have used AI for one year to two years.

Figure 2 shows the degree to which supply chain organizations have adopted AI overall. Almost half of organizations have not yet piloted the technology. Only 38% of organizations have moved beyond the piloting stage. Currently 21% of organizations are still considering the adoption of AI, although this number seems poised to change given AI’s status as a top trend affecting supply chain.

Interestingly, these percentages do not change much when looking at the degree of adoption for specific segments of the supply chain. For logistics and warehousing, only about 39% of organizations have moved beyond the piloting stage of AI technology. This indicates that organizations recognize the wide-ranging applicability of this technology for supply chain use, but it also means that its impact on employee skills is also wide-ranging.

Impact on employees

Many organizations believe that AI drives value through its impact on the number of employees needed for the supply chain. Of the organizations surveyed by APQC, 46% consider a reduction in headcount to be a top driver for deploying AI. A similar amount, 44%, consider headcount redeployment to be a top driver. As AI takes on more tasks previously completed by employees, organizations expect to be able to reduce the number of employees working in supply chain or redirect their skills to other areas.

However, as shown in Figure 3, organizations have not seen much churn in their supply chain employees. At the median, they have only seen a 6% change in the number of full-time equivalent (FTE) supply chain employees over the last 12 months.

Perhaps even more interesting is the fact that, at the median, organizations are actually adding more FTEs as a result of AI than they are eliminating or redeploying. At the 25th and 75th percentiles, there is no difference between the percentage of FTEs added due to AI and the percentage of FTEs eliminated

or redeployed.

This is counterintuitive to the widespread expectation that the use of AI will eliminate the tasks undertaken by some supply chain employees and thereby eliminate the need for these employees altogether. Rather than replacing employees, AI is changing the skills needed by supply chain professionals.

New skills needed

APQC has investigated the shift in skills needed among supply chain professionals. As a result of the adoption of AI, supply chain professionals are taking on tasks that require more social and deep work skills (or those enabling workers to focus intensely without distraction). AI and its resulting automation of tasks leaves the humans on staff to engage in work involving analysis and insight. Technology is no substitute for the relationship-building skills that support listening to stakeholders, communicating effectively with business partners, innovating and thinking strategically about how to approach challenges.

Figure 4 shows the top six skills organizations need their supply chain employees to develop or enhance as a result of the adoption of AI. Most of these are softer skills related to building relationships and

solving complex problems.

Communication and active listening are among the most needed skills. Supply chain employees must be able to discern the needs of their stakeholders and business partners, maintain positive relationships with partners and succinctly and clearly convey expectations to suppliers and other service providers. Creativity and innovation are among the most important skills because of the shifting nature of the modern supply chain. With supply chains forced to address previously unheard-of situations and disruption, such as the global pandemic, professionals must be able to identify novel solutions to keep the business running.

Related to innovation and creativity is the ability to think strategically and solve complex problems. AI can use data to predict any shifts necessary for manufacturing operations and planning. However, the technology should support smart decision making and problem solving by employees. This is where the soft skills of employees become critically important. Supply chain professionals must be able to look at evidence and make the best decision for the business, especially in situations in which there is no evident “right” answer.

Despite the overwhelming need for strategic and relationship-building skills, supply chains still need employees with more technical skill sets, such as in data science and analysis. These skills are necessary to adopt, maintain and support AI within supply chain.

Other skills that more than one-third of research participants want to see employees develop or enhance as a result of the adoption of AI include: complex problem solving, the ability to extract insights from new technology or systems, and agility and flexibility to adapt to change.

Invest in employee learning

As the skills needed by supply chain professionals working with AI continue to change, companies are investing in training and development to help their employees keep up. It is reassuring to see that employees are not being left to fend for themselves when it comes to honing the new skills and capabilities needed. APQC sees that this support is true regardless of industry. At the median, organizations are investing in seven days of employee learning per employee to ease this transition.

Organizations are also adjusting their learning budgets to ensure that their employees get the skills development they need. According to APQC’s research, AI accounts for a 30% change in learning budgets at the median.

Looking forward

The impact of AI on the supply chain will only continue to increase in coming years. With 40% of organizations currently considering or evaluating the use of AI for supply chain, there is a good chance that a company will be adopting it soon if it has not done so already. The key to retaining employees who will thrive in future supply chain roles is to ensure that they have the right mix of skills to support this

technology and leverage it strategically.

Many organizations have already committed to providing learning opportunities for supply chain professionals to develop or enhance critical skills. Although AI does not deliver the reduction in headcount some companies believed would come with it, retraining prevents skills shortages and is a smarter investment than trying to hire new individuals with the necessary skills. APQC encourages organizations to consider employee learning as part of the business case for investing in AI.

About APQC

APQC helps organizations work smarter, faster and with greater confidence. It is the world’s foremost authority in benchmarking, best practices, process and performance improvement, and knowledge management. APQC’s unique structure as a member-based nonprofit makes it a differentiator in the marketplace. APQC partners with more than 500 member organizations worldwide in all industries. With more than 40 years of experience, APQC remains the world’s leader in transforming organizations. Visit us at apqc.org and learn how you can make best practices your practices.

SC

MR

Latest Supply Chain News

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- More News

Latest Podcast

Explore

Explore

The Academy News

- AI, virtual reality is bringing experiential learning into the modern age

- Predicting stockouts: Enhancing FMCG resilience through data-driven insights

- Finding the Right Approach for Supply Chain Education

- The Supply Chain Triad

- Innovating Supply Chain Higher Education with Generative AI

- How Smart Supply Chain Management Boosts Brand Identity

- More The Academy

Latest Academy Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks