Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

September-October 2020

If it’s September, it must be time for Gartner’s take on the Top 25 supply chains. This marks the 16th year that Gartner has put together its list of the leading supply chains across he globe, a list that now also includes an additional five Masters. Those are companies that so consistently made the list year in and year out that they warranted a category all their own. You can read the article, and the web only material we publish on scmr.com, to find out what it takes to become a supply chain leader. Browse this issue archive.Need Help? Contact customer service 847-559-7581 More options

Shekar Natarajan

Title: Global Inventory, Supply Chain,Logistics and Services

Company: American Eagle Outfitters

Location: San Francisco, Calif.

Age:41

Years in Supply Chain Management: 17

Years at American Eagle: 2.5

How many people do you know who have worked for Coke and Pepsi, and for Walmart and Target? Those are some of the stops along the way for Shekar Natarajan, the global supply chain leader at American Eagle Outfitters, or AEO, since the end of 2018. Since arriving in the United states from India in 2001, Natarajan has taken a deliberate path through the various supply chain disciplines, working in project management, warehousing and distribution, transportation management and final mile delivery, planning and network design and supply chain transformation. Along

the way, he filed some 300 patents, was issued 73 and has authored books on Supply Chain. Those experiences uniquely prepared him for his role at AEO, where he owns a supply chain portfolio that encompasses all of those functions.

In addition to rethinking how the retailer takes its supply chain to market, Natarajan is also thinking about what comes next—what he refers to as Supply Chain 4.0, or the “open on-demand” supply chain model.

Those are just some of the things we discussed in a far-reaching interview.

SCMR: Shekar, when we spoke earlier, you mentioned that you came from a very humble background in India and had not originally planned to come to the United States. What brought you here in 2001?

Natarajan: It was a family necessity. My older brother moved to Alabama in 2000 to get his Ph.D. He broke his arm, and what little money he had was used for his medical requirements. He was in pretty bad shape and asked for help. I applied to a number of universities, and Georgia Tech was the school closest to my brother—I could jump on a bus and be there for the weekend in five hours. I enrolled in the industrial engineering graduate program to complement my undergraduate degree in mechanical engineering and mechatronics; it worked out great. I was thankful to get into a good school and have the opportunity to help my brother.

SCMR: So, you didn’t start out in supply chain management?

Natarajan: Not at all. My graduate research involved looking at how to pack electronics into a form factor—like a smart phone—to produce a reliable device. After graduating in 2003, it took seven months to find a role close to the core of my interests. Despite my frustration in the moment, this time turned out to be one of the best things for my career: I used those months to become further educated and gain exposure to things on broader spectrum. It was during this time that I began attending a program geared toward supply chain professionals, offered free-of-charge through the industrial engineering school. The series of courses brought together individuals from a variety of backgrounds, management levels and industries, all to learn the fundamentals of emergent supply chains: ways to think about warehousing, distribution, technologies, pick-to-light, robotics. I was exposed to a new dimension of learning: one with context, giving me a better understanding of the types of problems people were trying to solve. Before I knew it, I’d fallen in love with supply chain. It was a pivotal moment in my career.

SCMR: What were your first jobs in supply chain management?

Natarajan: My first supply chain job offer was in procurement at Starbucks; however, shortly after I was also offered a corporate development specialist position with a small, family-owned company in Hot Springs, Arkansas, that made rubber bands and specialty wristbands. I ultimately decided that I didn’t want to start out in a very narrow niche by taking a small role within a big company, so I chose rubber bands over Frappuccinos. My role cut across many different parts of the company, from logistics and production to commercial aspects. I ran projects to increase efficiency and create capacity in manufacturing; I challenged how the business thought about overhead allocations and ways to drive continuous improvement, while being involved in sales and marketing activities. The exposure gave me a business view rather than a merely functional perspective.

From there, I decided to try out a large organization and joined Coca-Cola Consolidated, the largest independent Coca-Cola bottler in the U.S. That was a big turning point for me. At the time, CPG and beverage companies were experiencing a proliferation of products—four times more than the infrastructure was designed to carry. The Coca-Cola bottling system had launched a very ambitious program to reduce the amount of non-value-added work in the supply chain. We were creating automation capabilities to pick, pack and move products in the warehouses and developing tools like scheduling software, geo-based planning and a delivery system with the right number of mixing centers and satellite networks. We wanted to modernize our last-mile delivery network—based off of an antiquated store delivery model that hadn’t changed in 50 years—and create a unique way to make delivery equipment and processes agnostic, from trucks to pallets. I was part of that transformation. We rolled out an enterprise-wide program that allowed us to plan out and execute the networks, including sourcing decisions. We came up with a one-touch model to simplify, streamline and eliminate unnecessary touches within the field by moving them back to a safer, more efficient DC environment My time with Coca-Cola taught me one of the most important lessons of my career: When you touch one piece of a supply chain, it affects everything. It taught me that to make good supply chain decisions, they must be rooted in good end-to-end business decisions, so that the capabilities and processes brought to life have positive impact throughout the entire business.

SCMR: What happened next?

Natarajan: From the start of my career, I’ve dedicated my focus to address major supply chain problems. So, from Coke, I went to Pepsi, which at the time was running center of excellence programs and rethinking its entire distribution fulfillment operations. In my warehousing, distribution and fulfillment role, I led a large transformation project to redesign distribution management across the full warehouse network for the bottling division. I wanted to get planning experience, so from Pepsi I went to Anheuser-Busch InBev to run demand and supply planning and inventory policy optimization. After getting tired of being known as the beverage guy, my next move was joining Disney; Disney was in the process of building an enterprise supply chain team, and my role was to support them with the best technology out there.

SCMR: You also worked for both Walmart and Target.

Natarajan: While working for Disney, Walmart recruited me to help solve a very unique problem at the time: competing with Amazon. Among Walmart’s strengths was an incredibly strong grocery supply chain with hyper-local presence. The team I led was tasked with developing a hyper-scalable model that made the online, home-grocery-shopping business feasible. We had to figure out how to get backroom processes so efficient that local pick up could be rolled out economically, and delivery was feasible. For the delivery piece, we wanted to leverage cars already driving past the stores all the time: Associates going to and from work, customers coming and going, even Uber drivers. It was a very untraditional yet super successful program for online delivery. While at Walmart, I also ran the emerging sciences group, where the team developed something like 1,800 patents ranging from autonomous vehicles, to drones taking inventory into the warehouse. I myself have somewhere around 300 patents. You name it, we worked on it. After that, I was recruited by Target to work on their end-to-end transformation, which included everything from network planning to inventory planning and control. Target had a very different approach from Walmart, and with that came more opportunities for innovation. One of the most important things I learned from my experience working on such exciting and transformative initiatives was that while supply chain is usually thought of as moving big boxes around, it can be so much more. Supply chain has the power to touch and improve people’s lives on a daily basis—that is exciting.

SCMR: What brought you to AEO?

Natarajan: With the exception of the rubber band maker, I had spent the majority of my career working for big companies and big brands. At the time I was recruited in 2018, I was living in the Bay Area, surrounded by the startup culture. Living at the intersection of innovation, technology and operations, and witnessing super successful platform companies like Uber emerge, I wanted to try something different. I was approached by AEO through a board recommendation. Jay Schottenstein, the CEO of AEO, is an inspirational leader and a visionary so I was immediately drawn to the company. I wondered how an entrepreneurial, nimble specialty retail player like AEO could use a supply chain advantage to punch above its weight. I joined AEO in late 2018.

SCMR: What were your marching orders?

Natarajan: My marching orders were: Don’t screw it up! At the time, AEO was contemplating its supply chain of the future. I have an amazing boss in Michael Rempell, the COO, who wanted a fresh set of eyes to strengthen the supply chain from a leadership and operations standpoint. After spending six months assessing the present state and unique capabilities I thought we’d need going forward, I presented an agenda to tame the retail tsunami for the next five years; that’s what we’re working on now. Change is always tough and needs to be well-supported, and I’m incredibly thankful to Jay, Michael, the rest of leadership, fellow peers and my team for enabling an amazing journey so far.

SCMR: As a supply chain leader, what’s in your portfolio of responsibilities?

Natarajan: I’m responsible for the 225 million units that we moved through the supply chain last year. That starts from the time we take custody of product from factories and move into our own networks in North America, as well as enabling availability for our global licensee business and other go-to-market formats. For North America specifically, my team is responsible for consolidating at origin, deconsolidating in the U.S. and floating into our fulfillment networks, enabling delivery to both customers and stores. Within that, my team is also responsible for global trade and compliance which includes things like maximizing free trade agreements, customs clearance, invoice processing and vendor-enablement activities.

I have complete oversight of our end-to-end distribution network, which consists of AEO-owned distribution centers throughout the U.S. and Canada, transloading operations and consolidation points in Asia and

Latin America.

In addition to operating functions such as logistics, distribution, fulfillment, inventory planning and allocation, I also have responsibility for transformation and modernization of the supply chain. Lastly, I also lead supply chain strategy and sciences.

SCMR: If you summed up what you’re trying to accomplish, how would you describe the approach?

Natarajan: Our goal is to make Supply Chain a strategic differentiator. So, we are creating modern, dynamic and distributed supply chain logistics operations that cater to the ever changing customer preferences and demands. Supply Chain is the engine that connects consumers to their favorite products. The team’s mission is to enable trust, transparency and speed, helping to create unparalleled loyalty to the brand.

SCMR: What are some of the changes you’re trying to make now?

Natarajan: We are on a multi-year, multi-stage journey and the first step of that journey was anchored around building a hyper-scalable and dynamic supply chain. This required us to rethink our entire enterprise value chain—refocusing the team on speed and accountability. We built our transformation flywheel on the premise that speed is the most important supply chain lever to push, while maintaining our cost and budgets; this could only be achieved through out-of-the-box thinking. We looked at every one of our processes, assessing the variability and time in each link of the supply chain and put our focus on reducing that variability—and liability—in the chain.

Stage 2 of this journey is the modernization of our omni-channel capability by creating a multi-tier fulfillment network based on core principles of speed, flexibility and innovation. Pragmatic use of technology and automation has been injected in all parts of Supply Chain from decision sciences to physical execution. Recent consumer trends and the pandemic have accelerated this journey and I am proud to say that we have made great progress in enabling this vision. I cannot thank them enough, I am so proud of the team, our culture and leadership’s support in all of this.

Here are a few examples: One is to move into a localized fulfillment model so we can offer same-day, next-day and two-day delivery to the majority of our customers. We also understand the infrastructure is one of the many levers but to really power this in a smart way, we needed to create data-driven algorithms and intelligence to dynamically position and flow inventory through our network. To maximize our capacity in the fulfillment network while enabling safety and resiliency we are augmenting our operations with on-demand robotics as a service. We have also deployed state of the art goods-to-person solutions.

SCMR: What do you think is the biggest accomplishment of the last 18 months?

Natarajan: It goes without saying that the biggest asset we have is our people. All of this needs great teams, and we are assembling the best of the best minds and drawing on the incredible passion of the our associates to bring this to life. And the teams have accomplished amazing things. For the year and a half my team has been in place, we’ve made a 180-degree shift. Instead of being regarded as just a cost of doing business, Supply Chain at AEO is now a competitive advantage. Pre-COVID, we reduced the time it takes our product to get from manufacturer to store by 20%. We were also able to reduce the time between product allocation to in-store arrival by 80%, going to stores daily. In doing so, our inbound and outbound processes have become faster, in turn prompting a need for our DC processes to get faster as well. It is so tough to make these transformational changes while continuing to manage everyday operations. It is truly remarkable what the entire company has been able to achieve. That goes to show the incredible spirit and entrepreneurship our company has which is the real secret sauce.

Big picture, we’re building core supply chain competencies that ultimately can be offered as a service to other specialty retailers. Think of it as Operations-as-a-Service. As an example, we’re looking to utilize capital assets and intellectual property the company already owns for last-mile delivery. We want to pivot to decentralized inventory and labor models to wrap all of this into a shared-asset framework that I call Supply Chain 4.0.

SCMR: We’ll come back to Supply Chain 4.0 in a minute. One of the big issues in every DC is labor. How are you addressing that problem?

Natarajan: We’re doing a number of things to take care of our associates. For instance, we allow associates to take bone conduction headphones onto the floor to listen to music; we also allow cell phones on the floor so associates can stay connected to their loved ones while working. We have moms, dads and primary caregivers who may need to get in touch with their kids while at work. I asked myself, “If I can do that, how can the associates do that and still have a safe environment?”

We also have associate perks for good behavior: If you’re picking fast, you earn points redeemable for a movie ticket or a gift card.

We’re transforming our hiring programs, making offers within 24 hours from the time someone shows up to interview. We’re using AI-based systems to attract talent and keep prospective hires engaged in the interview process. We continue to develop safety programs geared to bringing more assurance and peace of mind to associates.

We’re getting into flex labor and experimenting with a gig workforce in the DCs; this goes along with creating scalable supply chain capabilities which could be opened up to other companies. We’re creating a culture and environment where teams can “visioneer”—going beyond simply dreaming up scenarios: engineering the vision and executing with intensity.

SCMR: Have you made adjustments during COVID?

Natarajan: Yes, many. We’ve made our DCs a safer place to operate by implementing high-definition thermal scanners and social distancing protocols, hiring on-site nurses and utilizing static-cleaning measures. Our robotics program allows us to surge capacity without adding as many seasonal staff, thereby keeping density down.

At an industry level, COVID has accelerated the omni-channel requirements that were already straining small-and-mid-size businesses. To support consumer expectations for anytime, anywhere delivery, these businesses are forced to spend an increasing percentage of their budget on supply chain. As competition tightens, I believe this will lead to a mass extinction of retailers.

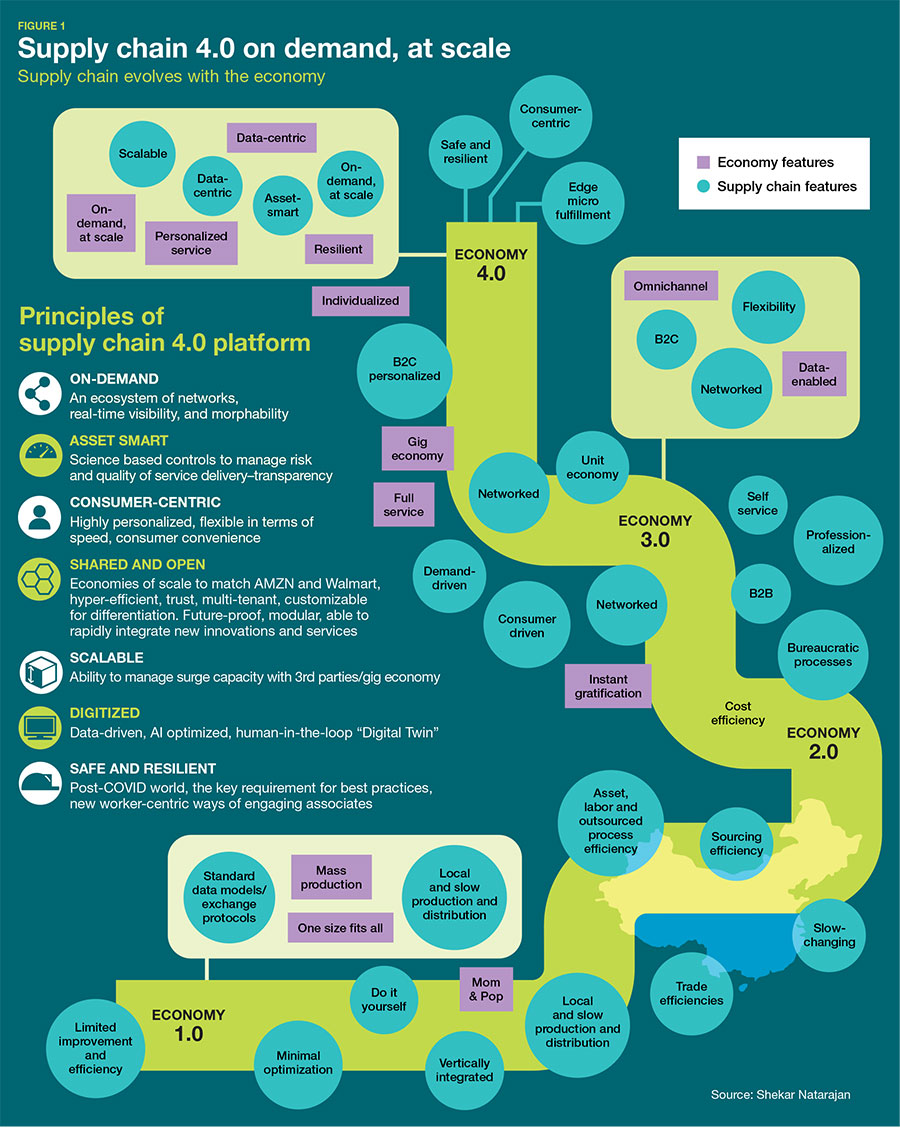

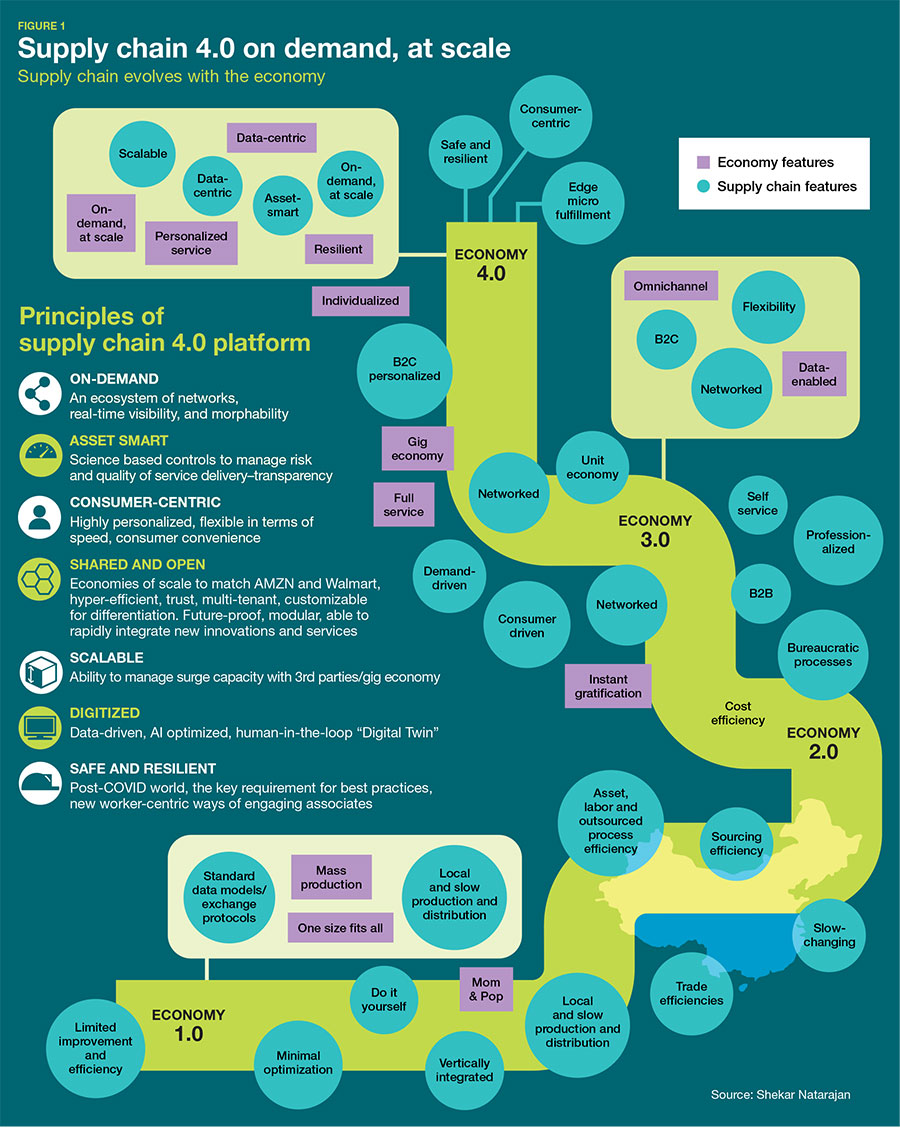

SCMR: Let’s talk about Supply Chain 4.0. You created a compelling infographic to illustrate the concept. So, what is Supply Chain 4.0 and how is it different?

Natarajan: The construct of supply chain management changes as the economy changes, so that changes in the economic paradigm bring paradigm shifts in supply chain. Since the first industrial revolution in the mid-18th century, we’ve already had three paradigm shifts in the economy and now we’re moving into the fourth.

SCMR: Walk us through those.

Natarajan: Economy 1.0 was simplistic. It was mass production with a one-size-fits-all, do-it-yourself approach. Think of Henry Ford’s famous phrase, “Any color car you want as long as it’s black.” We had mom and pop distribution; personalization meant going to the store. Supply chains weren’t so much supply chains as the loosely connected, vertically-integrated management of materials and production systems. They were slow moving with long lead times. The absence of technology resulted in a paper-based, transactional approach that lacked professionalism, with minimal opportunity for optimization and improvement outside of big companies like GM. Supply Chain 1.0 supported Economy 1.0.

In Economy 2.0, countries opened up their borders and created new trade lanes. The focus was on cost, so production and distribution moved offshore to the low-cost countries now in the news. Sourcing, labor and asset efficiency emerged as priorities for supply chain managers. Technology based on standardized data models was introduced, including the advent of ERP and planning systems, and the need for business connectivity became clear. Supply Chain 2.0 was supply-centric, with no real notion of demand. Supply chains were moving closer to the model we know today but remained slow to change nonetheless.

The advent of the Internet and new digital consumer models led to Economy 3.0. Amazon sparked a demand-and-consumer-driven wave that paved the way for the Airbnbs, Ubers, Facebooks and Googles of the world. It was all about instant gratification: Things like streamed media and consumable goods were only a click away. On the people side of the supply chain, the last economic crisis created a digital gig economy for workers. Supply Chain 3.0 was digitally heavy and asset light, requiring highly scalable systems. The focus shifted from business orders to fulfillment for the consumer; hence commerce had to shift from a self-service model to a full-service model where the company is expected to meet the consumer when and where they choose.

SCMR: That brings us to Supply Chain 4.0.

Natarajan: Yes. The consumption side of the economy has shifted again, this time from self-service to full-service, and on the distribution side from pallets and cases to units. In the past, consumers were told to go to the store and serve themselves. Now the focus is on full service, with the ability to meet the consumer where they want to meet us—at a store, at their house, curbside or any other location. The emphasis moves from distribution fulfillment to last-mile efficiencies and fulfillment capabilities. Supply Chain 4.0 requires on-demand, at-scale personalized services: Think of it as an Uber-like experience, individualized for the consumer, as applied to all business-to-business and business-to-consumer transactions. Getting lean—or cost-first focusing—is no longer of sole importance. Supply Chain 4.0 will be delivered in an open shared model that enables omni-channel full-service for a wide variety of retailers, without forcing them to surrender control of assets, data and brands. By enabling retailers to cooperate and aggregate scale, this open model will enable lower costs and more advanced technology than each player could achieve on their own. This enables retailers to focus on what matters the most—brand, product and customer experience.

SCMR: Lastly: What excites you the most about the future of supply chain?

Natarajan: Industries have been undergoing major transformations in recent years: Google set a new standard for information, the explosion of fintechs have forced a reset in the world of finance. But what about supply chain? Transforming supply chains is simply not enough—it’s time to revolutionize global trade. The winners of this game are going to re-imagine, re-engineer and re-distribute supply chain operations in the same way that Uber, Spotify and Airbnb have re-cast their sectors.

The global trade industry in its present state is a largely unorganized $38 trillion business poised for disruption. Technology’s constant evolution compounded by how quickly the individual components are changing—from sensory technology to cloud computing to consumer choices—created a recipe for reform. There’s an opportunity for a new renaissance: one in which a multitude of outcomes are created for professionals, for companies and for society as a whole.

The challenges and problems professionals will face tomorrow are not as we know them to be today, making way for exciting, new career paths and opportunities. Digital businesses created in the next decade will hold value far exceeding the value of any company today. These new businesses will be tasked with carrying the full burden of global trade while simultaneously maintaining integrity and the flexibility required to manage growing consumer needs. There are huge opportunities ahead within transportation as a service, the conversion of sensory data to platforms, the reorganization of networks and fixed-asset-leveraging solutions to create fixed capacity for the better management of the flow of goods. Whenever all systems undergo a reorganization, industries are forced to shed waste and do away with unsustainable practices. Newness is created; a more forward-thinking society emerges. Betterment for professionals, companies and for society as a whole will serve to drive the triple bottom line: people, profits and the planet.

Up until now, only the giants have been able to deliver on demand and at scale; what’s needed now is democratization. Supply chains are finally gaining their deserved prominence and new industries are being uncovered. New companies are forming right as the next generation of professionals enter the space, just in time to define what happens next. This shakedown and overhaul of all things will result in less wasteful, more sustainable digitalized economies. People, profits and the planet will be elevated. Bridging the gap between theory and application, Supply Chain 4.0 is the first step of a re-imagined, reformed and revolutionized global trade model; visioneering that model into existence is what most excites me about the future of supply chain.

American Eagle Outfitters Quick Facts

- FOUNDED: 1977

- MOST RECENT REVENUE: $4.3 billion, 2019, up 7% over 2018

- BRANDS: AE (American Eagle), Aerie and Todd Snyder

- NUMBER OF STORES: AEO operates 1,100 locations across the U.S., Canada, Mexico and Hong Kong and an additional 200 licensed stores located in 25 countries. A total of 81 countries are serviced through AEO’s digital business

- NUMBER OF CUSTOMERS SERVED: More than 20 million

- NUMBER OF FACILITIES (DISTRIBUTION CENTERS): AEO operates three distribution centers for e-fulfillment and store replenishment and an additional two supply chain nodes. In addition, the company operates three transload facilities to handline merchandise coming in through the ports and three consolidation distribution centers.

- NUMBER OF EMPLOYEES IN SUPPLY CHAIN: 240 and the corporate level and an additional 5,000 hourly associates

- NUMBER OF SKUs MANAGED: Active 64,075 Reserve 167,384

- THROUGHPUT: AEO sends out approximately 30 million shipments per year, comprising 242 million units

- INVENTORY: The company spends approximately $1.7 billion per year on inventory and carries an estimated $500 million in inventory at any given point in time

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

September-October 2020

If it’s September, it must be time for Gartner’s take on the Top 25 supply chains. This marks the 16th year that Gartner has put together its list of the leading supply chains across he globe, a list that now also… Browse this issue archive. Access your online digital edition. Download a PDF file of the September-October 2020 issue.Shekar Natarajan

Title: Global Inventory, Supply Chain,Logistics and Services

Company: American Eagle Outfitters

Location: San Francisco, Calif.

Age:41

Years in Supply Chain Management: 17

Years at American Eagle: 2.5

How many people do you know who have worked for Coke and Pepsi, and for Walmart and Target? Those are some of the stops along the way for Shekar Natarajan, the global supply chain leader at American Eagle Outfitters, or AEO, since the end of 2018. Since arriving in the United states from India in 2001, Natarajan has taken a deliberate path through the various supply chain disciplines, working in project management, warehousing and distribution, transportation management and final mile delivery, planning and network design and supply chain transformation. Along

the way, he filed some 300 patents, was issued 73 and has authored books on Supply Chain. Those experiences uniquely prepared him for his role at AEO, where he owns a supply chain portfolio that encompasses all of those functions.

In addition to rethinking how the retailer takes its supply chain to market, Natarajan is also thinking about what comes next—what he refers to as Supply Chain 4.0, or the “open on-demand” supply chain model.

Those are just some of the things we discussed in a far-reaching interview.

SCMR: Shekar, when we spoke earlier, you mentioned that you came from a very humble background in India and had not originally planned to come to the United States. What brought you here in 2001?

Natarajan: It was a family necessity. My older brother moved to Alabama in 2000 to get his Ph.D. He broke his arm, and what little money he had was used for his medical requirements. He was in pretty bad shape and asked for help. I applied to a number of universities, and Georgia Tech was the school closest to my brother—I could jump on a bus and be there for the weekend in five hours. I enrolled in the industrial engineering graduate program to complement my undergraduate degree in mechanical engineering and mechatronics; it worked out great. I was thankful to get into a good school and have the opportunity to help my brother.

SCMR: So, you didn’t start out in supply chain management?

Natarajan: Not at all. My graduate research involved looking at how to pack electronics into a form factor—like a smart phone—to produce a reliable device. After graduating in 2003, it took seven months to find a role close to the core of my interests. Despite my frustration in the moment, this time turned out to be one of the best things for my career: I used those months to become further educated and gain exposure to things on broader spectrum. It was during this time that I began attending a program geared toward supply chain professionals, offered free-of-charge through the industrial engineering school. The series of courses brought together individuals from a variety of backgrounds, management levels and industries, all to learn the fundamentals of emergent supply chains: ways to think about warehousing, distribution, technologies, pick-to-light, robotics. I was exposed to a new dimension of learning: one with context, giving me a better understanding of the types of problems people were trying to solve. Before I knew it, I’d fallen in love with supply chain. It was a pivotal moment in my career.

SCMR: What were your first jobs in supply chain management?

Natarajan: My first supply chain job offer was in procurement at Starbucks; however, shortly after I was also offered a corporate development specialist position with a small, family-owned company in Hot Springs, Arkansas, that made rubber bands and specialty wristbands. I ultimately decided that I didn’t want to start out in a very narrow niche by taking a small role within a big company, so I chose rubber bands over Frappuccinos. My role cut across many different parts of the company, from logistics and production to commercial aspects. I ran projects to increase efficiency and create capacity in manufacturing; I challenged how the business thought about overhead allocations and ways to drive continuous improvement, while being involved in sales and marketing activities. The exposure gave me a business view rather than a merely functional perspective.

From there, I decided to try out a large organization and joined Coca-Cola Consolidated, the largest independent Coca-Cola bottler in the U.S. That was a big turning point for me. At the time, CPG and beverage companies were experiencing a proliferation of products—four times more than the infrastructure was designed to carry. The Coca-Cola bottling system had launched a very ambitious program to reduce the amount of non-value-added work in the supply chain. We were creating automation capabilities to pick, pack and move products in the warehouses and developing tools like scheduling software, geo-based planning and a delivery system with the right number of mixing centers and satellite networks. We wanted to modernize our last-mile delivery network—based off of an antiquated store delivery model that hadn’t changed in 50 years—and create a unique way to make delivery equipment and processes agnostic, from trucks to pallets. I was part of that transformation. We rolled out an enterprise-wide program that allowed us to plan out and execute the networks, including sourcing decisions. We came up with a one-touch model to simplify, streamline and eliminate unnecessary touches within the field by moving them back to a safer, more efficient DC environment My time with Coca-Cola taught me one of the most important lessons of my career: When you touch one piece of a supply chain, it affects everything. It taught me that to make good supply chain decisions, they must be rooted in good end-to-end business decisions, so that the capabilities and processes brought to life have positive impact throughout the entire business.

SCMR: What happened next?

Natarajan: From the start of my career, I’ve dedicated my focus to address major supply chain problems. So, from Coke, I went to Pepsi, which at the time was running center of excellence programs and rethinking its entire distribution fulfillment operations. In my warehousing, distribution and fulfillment role, I led a large transformation project to redesign distribution management across the full warehouse network for the bottling division. I wanted to get planning experience, so from Pepsi I went to Anheuser-Busch InBev to run demand and supply planning and inventory policy optimization. After getting tired of being known as the beverage guy, my next move was joining Disney; Disney was in the process of building an enterprise supply chain team, and my role was to support them with the best technology out there.

SCMR: You also worked for both Walmart and Target.

Natarajan: While working for Disney, Walmart recruited me to help solve a very unique problem at the time: competing with Amazon. Among Walmart’s strengths was an incredibly strong grocery supply chain with hyper-local presence. The team I led was tasked with developing a hyper-scalable model that made the online, home-grocery-shopping business feasible. We had to figure out how to get backroom processes so efficient that local pick up could be rolled out economically, and delivery was feasible. For the delivery piece, we wanted to leverage cars already driving past the stores all the time: Associates going to and from work, customers coming and going, even Uber drivers. It was a very untraditional yet super successful program for online delivery. While at Walmart, I also ran the emerging sciences group, where the team developed something like 1,800 patents ranging from autonomous vehicles, to drones taking inventory into the warehouse. I myself have somewhere around 300 patents. You name it, we worked on it. After that, I was recruited by Target to work on their end-to-end transformation, which included everything from network planning to inventory planning and control. Target had a very different approach from Walmart, and with that came more opportunities for innovation. One of the most important things I learned from my experience working on such exciting and transformative initiatives was that while supply chain is usually thought of as moving big boxes around, it can be so much more. Supply chain has the power to touch and improve people’s lives on a daily basis—that is exciting.

SCMR: What brought you to AEO?

Natarajan: With the exception of the rubber band maker, I had spent the majority of my career working for big companies and big brands. At the time I was recruited in 2018, I was living in the Bay Area, surrounded by the startup culture. Living at the intersection of innovation, technology and operations, and witnessing super successful platform companies like Uber emerge, I wanted to try something different. I was approached by AEO through a board recommendation. Jay Schottenstein, the CEO of AEO, is an inspirational leader and a visionary so I was immediately drawn to the company. I wondered how an entrepreneurial, nimble specialty retail player like AEO could use a supply chain advantage to punch above its weight. I joined AEO in late 2018.

SCMR: What were your marching orders?

Natarajan: My marching orders were: Don’t screw it up! At the time, AEO was contemplating its supply chain of the future. I have an amazing boss in Michael Rempell, the COO, who wanted a fresh set of eyes to strengthen the supply chain from a leadership and operations standpoint. After spending six months assessing the present state and unique capabilities I thought we’d need going forward, I presented an agenda to tame the retail tsunami for the next five years; that’s what we’re working on now. Change is always tough and needs to be well-supported, and I’m incredibly thankful to Jay, Michael, the rest of leadership, fellow peers and my team for enabling an amazing journey so far.

SCMR: As a supply chain leader, what’s in your portfolio of responsibilities?

Natarajan: I’m responsible for the 225 million units that we moved through the supply chain last year. That starts from the time we take custody of product from factories and move into our own networks in North America, as well as enabling availability for our global licensee business and other go-to-market formats. For North America specifically, my team is responsible for consolidating at origin, deconsolidating in the U.S. and floating into our fulfillment networks, enabling delivery to both customers and stores. Within that, my team is also responsible for global trade and compliance which includes things like maximizing free trade agreements, customs clearance, invoice processing and vendor-enablement activities.

I have complete oversight of our end-to-end distribution network, which consists of AEO-owned distribution centers throughout the U.S. and Canada, transloading operations and consolidation points in Asia and

Latin America.

In addition to operating functions such as logistics, distribution, fulfillment, inventory planning and allocation, I also have responsibility for transformation and modernization of the supply chain. Lastly, I also lead supply chain strategy and sciences.

SCMR: If you summed up what you’re trying to accomplish, how would you describe the approach?

Natarajan: Our goal is to make Supply Chain a strategic differentiator. So, we are creating modern, dynamic and distributed supply chain logistics operations that cater to the ever changing customer preferences and demands. Supply Chain is the engine that connects consumers to their favorite products. The team’s mission is to enable trust, transparency and speed, helping to create unparalleled loyalty to the brand.

SCMR: What are some of the changes you’re trying to make now?

Natarajan: We are on a multi-year, multi-stage journey and the first step of that journey was anchored around building a hyper-scalable and dynamic supply chain. This required us to rethink our entire enterprise value chain—refocusing the team on speed and accountability. We built our transformation flywheel on the premise that speed is the most important supply chain lever to push, while maintaining our cost and budgets; this could only be achieved through out-of-the-box thinking. We looked at every one of our processes, assessing the variability and time in each link of the supply chain and put our focus on reducing that variability—and liability—in the chain.

Stage 2 of this journey is the modernization of our omni-channel capability by creating a multi-tier fulfillment network based on core principles of speed, flexibility and innovation. Pragmatic use of technology and automation has been injected in all parts of Supply Chain from decision sciences to physical execution. Recent consumer trends and the pandemic have accelerated this journey and I am proud to say that we have made great progress in enabling this vision. I cannot thank them enough, I am so proud of the team, our culture and leadership’s support in all of this.

Here are a few examples: One is to move into a localized fulfillment model so we can offer same-day, next-day and two-day delivery to the majority of our customers. We also understand the infrastructure is one of the many levers but to really power this in a smart way, we needed to create data-driven algorithms and intelligence to dynamically position and flow inventory through our network. To maximize our capacity in the fulfillment network while enabling safety and resiliency we are augmenting our operations with on-demand robotics as a service. We have also deployed state of the art goods-to-person solutions.

SCMR: What do you think is the biggest accomplishment of the last 18 months?

Natarajan: It goes without saying that the biggest asset we have is our people. All of this needs great teams, and we are assembling the best of the best minds and drawing on the incredible passion of the our associates to bring this to life. And the teams have accomplished amazing things. For the year and a half my team has been in place, we’ve made a 180-degree shift. Instead of being regarded as just a cost of doing business, Supply Chain at AEO is now a competitive advantage. Pre-COVID, we reduced the time it takes our product to get from manufacturer to store by 20%. We were also able to reduce the time between product allocation to in-store arrival by 80%, going to stores daily. In doing so, our inbound and outbound processes have become faster, in turn prompting a need for our DC processes to get faster as well. It is so tough to make these transformational changes while continuing to manage everyday operations. It is truly remarkable what the entire company has been able to achieve. That goes to show the incredible spirit and entrepreneurship our company has which is the real secret sauce.

Big picture, we’re building core supply chain competencies that ultimately can be offered as a service to other specialty retailers. Think of it as Operations-as-a-Service. As an example, we’re looking to utilize capital assets and intellectual property the company already owns for last-mile delivery. We want to pivot to decentralized inventory and labor models to wrap all of this into a shared-asset framework that I call Supply Chain 4.0.

SCMR: We’ll come back to Supply Chain 4.0 in a minute. One of the big issues in every DC is labor. How are you addressing that problem?

Natarajan: We’re doing a number of things to take care of our associates. For instance, we allow associates to take bone conduction headphones onto the floor to listen to music; we also allow cell phones on the floor so associates can stay connected to their loved ones while working. We have moms, dads and primary caregivers who may need to get in touch with their kids while at work. I asked myself, “If I can do that, how can the associates do that and still have a safe environment?”

We also have associate perks for good behavior: If you’re picking fast, you earn points redeemable for a movie ticket or a gift card.

We’re transforming our hiring programs, making offers within 24 hours from the time someone shows up to interview. We’re using AI-based systems to attract talent and keep prospective hires engaged in the interview process. We continue to develop safety programs geared to bringing more assurance and peace of mind to associates.

We’re getting into flex labor and experimenting with a gig workforce in the DCs; this goes along with creating scalable supply chain capabilities which could be opened up to other companies. We’re creating a culture and environment where teams can “visioneer”—going beyond simply dreaming up scenarios: engineering the vision and executing with intensity.

SCMR: Have you made adjustments during COVID?

Natarajan: Yes, many. We’ve made our DCs a safer place to operate by implementing high-definition thermal scanners and social distancing protocols, hiring on-site nurses and utilizing static-cleaning measures. Our robotics program allows us to surge capacity without adding as many seasonal staff, thereby keeping density down.

At an industry level, COVID has accelerated the omni-channel requirements that were already straining small-and-mid-size businesses. To support consumer expectations for anytime, anywhere delivery, these businesses are forced to spend an increasing percentage of their budget on supply chain. As competition tightens, I believe this will lead to a mass extinction of retailers.

SCMR: Let’s talk about Supply Chain 4.0. You created a compelling infographic to illustrate the concept. So, what is Supply Chain 4.0 and how is it different?

Natarajan: The construct of supply chain management changes as the economy changes, so that changes in the economic paradigm bring paradigm shifts in supply chain. Since the first industrial revolution in the mid-18th century, we’ve already had three paradigm shifts in the economy and now we’re moving into the fourth.

SCMR: Walk us through those.

Natarajan: Economy 1.0 was simplistic. It was mass production with a one-size-fits-all, do-it-yourself approach. Think of Henry Ford’s famous phrase, “Any color car you want as long as it’s black.” We had mom and pop distribution; personalization meant going to the store. Supply chains weren’t so much supply chains as the loosely connected, vertically-integrated management of materials and production systems. They were slow moving with long lead times. The absence of technology resulted in a paper-based, transactional approach that lacked professionalism, with minimal opportunity for optimization and improvement outside of big companies like GM. Supply Chain 1.0 supported Economy 1.0.

In Economy 2.0, countries opened up their borders and created new trade lanes. The focus was on cost, so production and distribution moved offshore to the low-cost countries now in the news. Sourcing, labor and asset efficiency emerged as priorities for supply chain managers. Technology based on standardized data models was introduced, including the advent of ERP and planning systems, and the need for business connectivity became clear. Supply Chain 2.0 was supply-centric, with no real notion of demand. Supply chains were moving closer to the model we know today but remained slow to change nonetheless.

The advent of the Internet and new digital consumer models led to Economy 3.0. Amazon sparked a demand-and-consumer-driven wave that paved the way for the Airbnbs, Ubers, Facebooks and Googles of the world. It was all about instant gratification: Things like streamed media and consumable goods were only a click away. On the people side of the supply chain, the last economic crisis created a digital gig economy for workers. Supply Chain 3.0 was digitally heavy and asset light, requiring highly scalable systems. The focus shifted from business orders to fulfillment for the consumer; hence commerce had to shift from a self-service model to a full-service model where the company is expected to meet the consumer when and where they choose.

SCMR: That brings us to Supply Chain 4.0.

Natarajan: Yes. The consumption side of the economy has shifted again, this time from self-service to full-service, and on the distribution side from pallets and cases to units. In the past, consumers were told to go to the store and serve themselves. Now the focus is on full service, with the ability to meet the consumer where they want to meet us—at a store, at their house, curbside or any other location. The emphasis moves from distribution fulfillment to last-mile efficiencies and fulfillment capabilities. Supply Chain 4.0 requires on-demand, at-scale personalized services: Think of it as an Uber-like experience, individualized for the consumer, as applied to all business-to-business and business-to-consumer transactions. Getting lean—or cost-first focusing—is no longer of sole importance. Supply Chain 4.0 will be delivered in an open shared model that enables omni-channel full-service for a wide variety of retailers, without forcing them to surrender control of assets, data and brands. By enabling retailers to cooperate and aggregate scale, this open model will enable lower costs and more advanced technology than each player could achieve on their own. This enables retailers to focus on what matters the most—brand, product and customer experience.

SCMR: Lastly: What excites you the most about the future of supply chain?

Natarajan: Industries have been undergoing major transformations in recent years: Google set a new standard for information, the explosion of fintechs have forced a reset in the world of finance. But what about supply chain? Transforming supply chains is simply not enough—it’s time to revolutionize global trade. The winners of this game are going to re-imagine, re-engineer and re-distribute supply chain operations in the same way that Uber, Spotify and Airbnb have re-cast their sectors.

The global trade industry in its present state is a largely unorganized $38 trillion business poised for disruption. Technology’s constant evolution compounded by how quickly the individual components are changing—from sensory technology to cloud computing to consumer choices—created a recipe for reform. There’s an opportunity for a new renaissance: one in which a multitude of outcomes are created for professionals, for companies and for society as a whole.

The challenges and problems professionals will face tomorrow are not as we know them to be today, making way for exciting, new career paths and opportunities. Digital businesses created in the next decade will hold value far exceeding the value of any company today. These new businesses will be tasked with carrying the full burden of global trade while simultaneously maintaining integrity and the flexibility required to manage growing consumer needs. There are huge opportunities ahead within transportation as a service, the conversion of sensory data to platforms, the reorganization of networks and fixed-asset-leveraging solutions to create fixed capacity for the better management of the flow of goods. Whenever all systems undergo a reorganization, industries are forced to shed waste and do away with unsustainable practices. Newness is created; a more forward-thinking society emerges. Betterment for professionals, companies and for society as a whole will serve to drive the triple bottom line: people, profits and the planet.

Up until now, only the giants have been able to deliver on demand and at scale; what’s needed now is democratization. Supply chains are finally gaining their deserved prominence and new industries are being uncovered. New companies are forming right as the next generation of professionals enter the space, just in time to define what happens next. This shakedown and overhaul of all things will result in less wasteful, more sustainable digitalized economies. People, profits and the planet will be elevated. Bridging the gap between theory and application, Supply Chain 4.0 is the first step of a re-imagined, reformed and revolutionized global trade model; visioneering that model into existence is what most excites me about the future of supply chain.

American Eagle Outfitters Quick Facts

- FOUNDED: 1977

- MOST RECENT REVENUE: $4.3 billion, 2019, up 7% over 2018

- BRANDS: AE (American Eagle), Aerie and Todd Snyder

- NUMBER OF STORES: AEO operates 1,100 locations across the U.S., Canada, Mexico and Hong Kong and an additional 200 licensed stores located in 25 countries. A total of 81 countries are serviced through AEO’s digital business

- NUMBER OF CUSTOMERS SERVED: More than 20 million

- NUMBER OF FACILITIES (DISTRIBUTION CENTERS): AEO operates three distribution centers for e-fulfillment and store replenishment and an additional two supply chain nodes. In addition, the company operates three transload facilities to handline merchandise coming in through the ports and three consolidation distribution centers.

- NUMBER OF EMPLOYEES IN SUPPLY CHAIN: 240 and the corporate level and an additional 5,000 hourly associates

- NUMBER OF SKUs MANAGED: Active 64,075 Reserve 167,384

- THROUGHPUT: AEO sends out approximately 30 million shipments per year, comprising 242 million units

- INVENTORY: The company spends approximately $1.7 billion per year on inventory and carries an estimated $500 million in inventory at any given point in time

SC

MR

Latest Supply Chain News

Latest Podcast

Explore

Explore

Business Management News

- U.S.-bound containerized import shipments are up in June and first half of 2024

- Expand supply chain metrics to cover the complete customer experience

- When disaster strikes, the supply chain becomes the key to life

- Leadership development for supply chain leaders

- A smarter approach to sustainability is vital for healthy, resilient supply chains

- When the scales tilt: Making vaccine access work for all

- More Business Management

Latest Business Management Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks