Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

September-October 2021

This time every year, we publish Gartner’s Top 25 supply chains, the annual list of the supply chains that have made it to the top, a list that now also includes 5 Masters, or companies that have consistently outperformed year after year. You can read the article in this issue, along with the web exclusive material we publish on scmr.com, to find out what it takes to become a supply chain leader. Browse this issue archive.Need Help? Contact customer service 847-559-7581 More options

As the past year and a half has shown, disruption and uncertainty are the new normal. This is especially true for supply chains, which will continue to face disruptions such as the ongoing impact of a global pandemic, as well as natural disasters and weather events that make a more local impact.

Even prior to the pandemic, a majority of supply chains experienced some type of disruption. In a March 2020 survey, supply chain professionals also anticipated that they would experience more disruptions in the near future. None of us could have known what would follow shortly after. However, knowing that COVID-19 will eventually be replaced by some other disruption, whether on a local, regional or global scale, it is time for organizations to determine how they will prepare for change.

View the related APQC infographic: How supply chain can support innovation

Times of uncertainty present opportunities for organizations to innovate and experiment. Although new ideas and methods present additional change, when innovation is structured and intentional, it enables an organization to take meaningful action.

Innovation often brings to mind product development. The supply chain has the opportunity to affect new products by providing expertise in sourcing new or different materials. It can also support innovation of internal processes by providing a variety of perspectives—including manufacturing and logistics considerations—that can result in a stronger organization.

Linking disruption to innovation

APQC asked leading thinkers on innovation and disruption how organizations can recover from the events of the past year. Scott Anthony from Innosight and Stephen Wunker from New Markets Advisors both encourage organizations to embrace change and use the lessons learned over the past year to inform innovations moving forward.

Consider customer needs. Anthony points out that changes resulting from disruptions can have long-term effects on the needs of customers. Organizations must determine which needs are likely to revert to pre-disruption levels and which changes are likely to stay. Despite disruptions, organizations must be capable of innovating to improve their processes and meet the changing needs of customers.

Organizations must have a rapid response strategy in place that enables it to be flexible enough to find innovative solutions to immediate problems. Anthony also encourages organizations to take more control of their future by identifying areas of long-term strategic focus. This should be an intentional process that seeks to meet a customer need through a solution that aligns with the organization’s capabilities.

Sustaining innovation. In his advice to organizations, Wunker notes that many of the innovative strategies organizations developed during the pandemic can be adopted for future disruptions. To ensure that their innovation efforts can be sustained, Wunker advises organizations to adopt key practices.

One is to take a broad look at future trends and their associated risks and opportunities. Organizations can then use this information to develop long-term strategies that inform innovation. Although innovation is often thought of in the context of product development, it can also lead to the development of new business models or different ways of engaging with customers.

According to Wunker, a key part of innovation is the ability to test scenarios to determine the potential impacts associated with different options. Once an organization has implemented a new process or product, it must have a system in place to capture findings and lessons learned. This allows it to quickly make any necessary adaptations to improve on the innovation and apply lessons to future ideas.

Another important practice is to allow employees to innovate on the job. The disruption caused by COVID-19 forced employees to adapt quickly and learn while doing. Many organizations realized that their employees were the source of tactics or hacks for responding quickly, setting the stage for the organization’s ability to

innovate in the future.

Organizations should follow Anthony’s and Wunker’s advice and determine how they can sustain innovation that allows them to recover from disruptions and meet changing customer needs. Data from APQC reveals how much this is needed.

Adding innovation to the flow of work

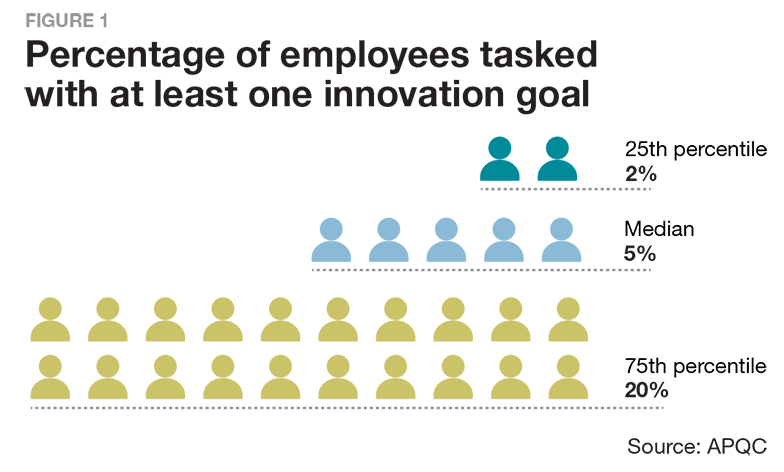

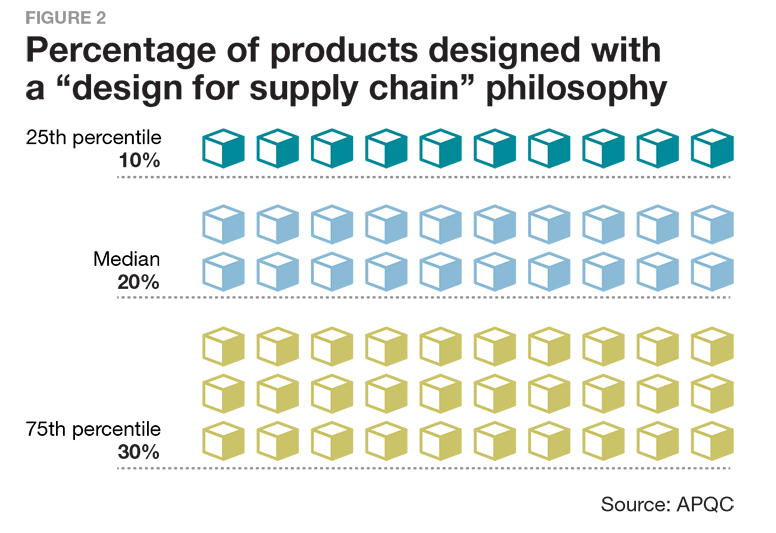

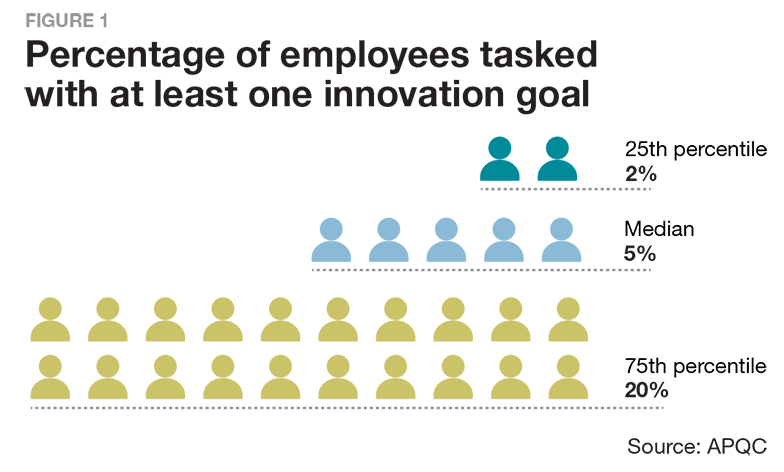

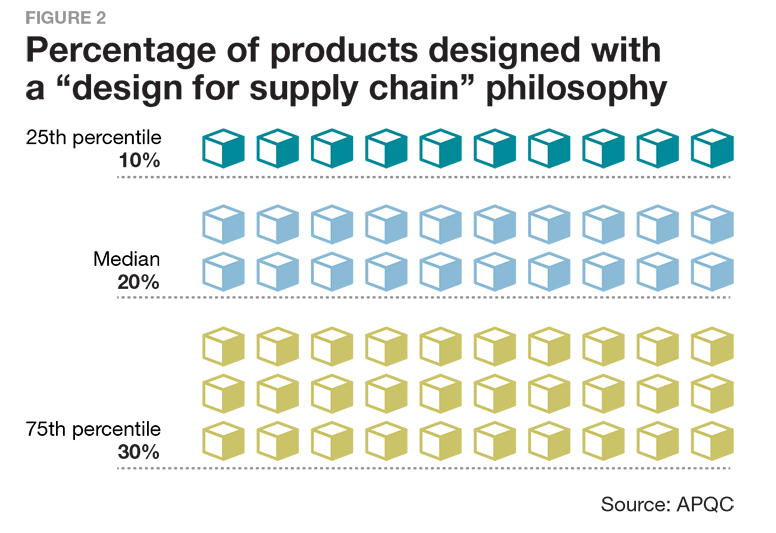

APQC collects data related to innovation through its Open Standards Benchmarking effort. One measure is the percentage of employees with innovation as a goal, which indicates an organization’s overall dedication to making innovation a priority. The other is the percentage of products designed with a “design for supply chain” philosophy, or an approach that considers input from supply chain professionals to reduce materials costs and take into account supply chain capabilities.

As shown in Figure 1, at the median, organizations task only 5% of their employees with at least one innovation goal. That means the vast majority of organizations’ employees are not expected to incorporate innovation into their day-to-day jobs. Even at the 75th percentile, organizations task only 20% of their employees with innovation goals.

Although employees may be developing new ways of working or new ways of meeting the needs of customers, organizations have not formalized innovation by adding it to employee goals. This puts companies at a disadvantage because they are unable to track the amounts and types of innovation developed internally. By creating innovation goals for employees, organizations solidify their commitment to improvement and empower their employees to consider and share ideas. For the supply chain, this also means collaboration with strategic partners to develop and implement mutually beneficial practices and approaches.

The involvement of supply chain in product development also presents an opportunity for organizations to use innovation to their advantage. As shown in Figure 2, at the median organizations design 20% of their products with input on supply chain costs and capabilities early in the development process. At the 75th percentile, the amount shifts to 30%.

The design for supply chain philosophy is an example of how internal collaboration can drive effective innovation. By considering supply chain costs, risks and capabilities, organizations can lower the costs to produce new products and set themselves up for competitive advantage. Supply chain needs to be part of innovation and product development from the start—not just an afterthought. Rather than operating in silos, organizations should integrate sourcing and procurement into the process early to source new or different materials needed. It’s also important to get manufacturing engaged before launch to help plan how and where to produce new products. And by involving logistics from the start, organizations can think through how to handle inbound and outbound transportation for new products and be prepared to avoid or reduce the potential of backlogs for customers.

The integration of innovation into supply chain and otherwise, can clearly bolster a company’s resilience. To make innovation central to organizational culture, leaders must make it a deliberate and strategic priority for the business.

Using open innovation to support resilience

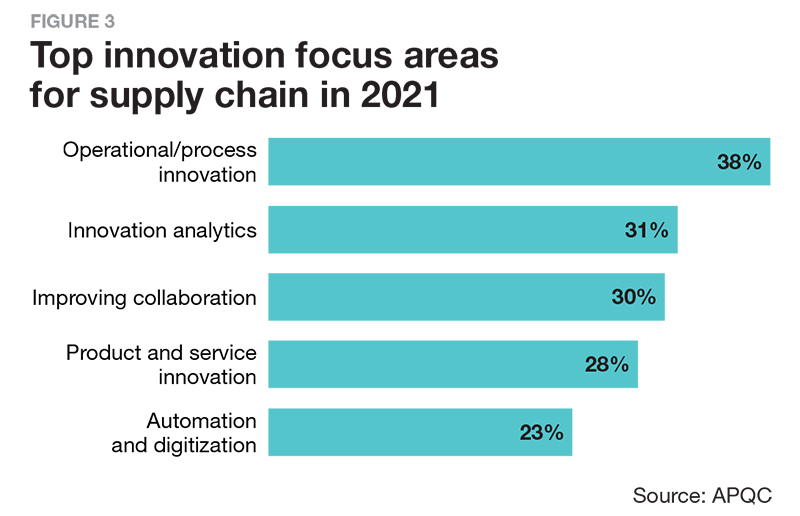

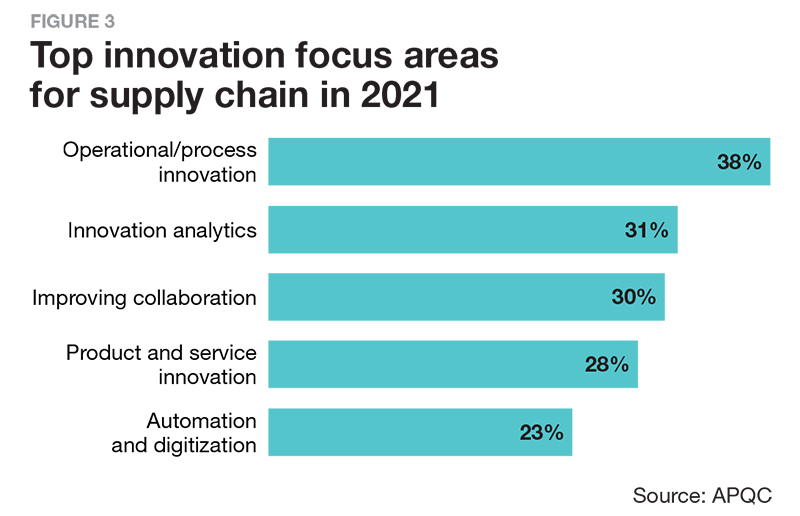

Many supply chains have had to adjust to the last 18 months by adopting new and innovative ways of conducting business and meeting the changing needs of customers. The need for innovation in supply chain was already apparent when APQC conducted its annual of supply chain priorities survey at the beginning of 2021. In it, 71%

of supply chain professionals said that innovation would be a top area of focus for their organizations in the coming year.

These professionals indicated that operational and process innovation was a priority for the year (see Figure 3). Product and service innovation had 10% fewer professionals indicating that it was a top focus area for the year.

Although the supply chain can play a key role in product development, organizations should think of innovation beyond the creation of products and services. To remain competitive, they need to reimagine their operations and processes to adjust to permanent changes and make themselves more resilient to future disruptions. They must also recognize the importance of supporting a culture of collaboration.

Open innovation provides an opportunity for the supply chain to foster collaboration and leverage external relationships to source ideas. From an operations and process standpoint, it can help companies get work done more efficiently at a lower cost. By increasing internal collaboration and work with external partners, organizations can often generate more and better ideas.

APQC recommends that organizations adopting open innovation do so in a strategic, intentional way. Innovation for its own sake and without structure can lead to changes that do not stick. Organizations must ensure that there are identified roles, processes and measures for continuous improvement. However, leaders must balance this with the flexibility to evaluate and eliminate barriers that are hindering the innovation effort.

What open innovation can look like has changed in the age of COVID-19. Greater access to online communication tools has provided another way for internal functions to collaborate. Yet there is still a benefit to proximity. Companies can provide in-person opportunities for internal collaboration once it is safe. They can also use geographical proximity to partners to support the sharing of mutually beneficial ideas.

Regardless of an organization’s size or industry, it has most likely had to innovate during the pandemic. To remain competitive through future disruptions and to harness the power of innovation to improve operations, organizations and their supply chains should be intentional about how they can encourage internal idea sharing and leverage external relationships.

About APQC

APQC helps organizations work smarter, faster and with greater confidence. It is the world’s foremost authority in benchmarking, best practices, process and performance improvement, and knowledge management. APQC’s unique structure as a member-based nonprofit makes it a differentiator in the marketplace. APQC partners with more than 500 member organizations worldwide in all industries. With more than 40 years of experience, APQC remains the world’s leader in transforming organizations. Visit us at apqc.org and learn how you can make best practices your practices.

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

September-October 2021

This time every year, we publish Gartner’s Top 25 supply chains, the annual list of the supply chains that have made it to the top, a list that now also includes 5 Masters, or companies that have consistently… Browse this issue archive. Access your online digital edition. Download a PDF file of the September-October 2021 issue.As the past year and a half has shown, disruption and uncertainty are the new normal. This is especially true for supply chains, which will continue to face disruptions such as the ongoing impact of a global pandemic, as well as natural disasters and weather events that make a more local impact.

Even prior to the pandemic, a majority of supply chains experienced some type of disruption. In a March 2020 survey, supply chain professionals also anticipated that they would experience more disruptions in the near future. None of us could have known what would follow shortly after. However, knowing that COVID-19 will eventually be replaced by some other disruption, whether on a local, regional or global scale, it is time for organizations to determine how they will prepare for change.

View the related APQC infographic: How supply chain can support innovation

Times of uncertainty present opportunities for organizations to innovate and experiment. Although new ideas and methods present additional change, when innovation is structured and intentional, it enables an organization to take meaningful action.

Innovation often brings to mind product development. The supply chain has the opportunity to affect new products by providing expertise in sourcing new or different materials. It can also support innovation of internal processes by providing a variety of perspectives—including manufacturing and logistics considerations—that can result in a stronger organization.

Linking disruption to innovation

APQC asked leading thinkers on innovation and disruption how organizations can recover from the events of the past year. Scott Anthony from Innosight and Stephen Wunker from New Markets Advisors both encourage organizations to embrace change and use the lessons learned over the past year to inform innovations moving forward.

Consider customer needs. Anthony points out that changes resulting from disruptions can have long-term effects on the needs of customers. Organizations must determine which needs are likely to revert to pre-disruption levels and which changes are likely to stay. Despite disruptions, organizations must be capable of innovating to improve their processes and meet the changing needs of customers.

Organizations must have a rapid response strategy in place that enables it to be flexible enough to find innovative solutions to immediate problems. Anthony also encourages organizations to take more control of their future by identifying areas of long-term strategic focus. This should be an intentional process that seeks to meet a customer need through a solution that aligns with the organization’s capabilities.

Sustaining innovation. In his advice to organizations, Wunker notes that many of the innovative strategies organizations developed during the pandemic can be adopted for future disruptions. To ensure that their innovation efforts can be sustained, Wunker advises organizations to adopt key practices.

One is to take a broad look at future trends and their associated risks and opportunities. Organizations can then use this information to develop long-term strategies that inform innovation. Although innovation is often thought of in the context of product development, it can also lead to the development of new business models or different ways of engaging with customers.

According to Wunker, a key part of innovation is the ability to test scenarios to determine the potential impacts associated with different options. Once an organization has implemented a new process or product, it must have a system in place to capture findings and lessons learned. This allows it to quickly make any necessary adaptations to improve on the innovation and apply lessons to future ideas.

Another important practice is to allow employees to innovate on the job. The disruption caused by COVID-19 forced employees to adapt quickly and learn while doing. Many organizations realized that their employees were the source of tactics or hacks for responding quickly, setting the stage for the organization’s ability to

innovate in the future.

Organizations should follow Anthony’s and Wunker’s advice and determine how they can sustain innovation that allows them to recover from disruptions and meet changing customer needs. Data from APQC reveals how much this is needed.

Adding innovation to the flow of work

APQC collects data related to innovation through its Open Standards Benchmarking effort. One measure is the percentage of employees with innovation as a goal, which indicates an organization’s overall dedication to making innovation a priority. The other is the percentage of products designed with a “design for supply chain” philosophy, or an approach that considers input from supply chain professionals to reduce materials costs and take into account supply chain capabilities.

As shown in Figure 1, at the median, organizations task only 5% of their employees with at least one innovation goal. That means the vast majority of organizations’ employees are not expected to incorporate innovation into their day-to-day jobs. Even at the 75th percentile, organizations task only 20% of their employees with innovation goals.

Although employees may be developing new ways of working or new ways of meeting the needs of customers, organizations have not formalized innovation by adding it to employee goals. This puts companies at a disadvantage because they are unable to track the amounts and types of innovation developed internally. By creating innovation goals for employees, organizations solidify their commitment to improvement and empower their employees to consider and share ideas. For the supply chain, this also means collaboration with strategic partners to develop and implement mutually beneficial practices and approaches.

The involvement of supply chain in product development also presents an opportunity for organizations to use innovation to their advantage. As shown in Figure 2, at the median organizations design 20% of their products with input on supply chain costs and capabilities early in the development process. At the 75th percentile, the amount shifts to 30%.

The design for supply chain philosophy is an example of how internal collaboration can drive effective innovation. By considering supply chain costs, risks and capabilities, organizations can lower the costs to produce new products and set themselves up for competitive advantage. Supply chain needs to be part of innovation and product development from the start—not just an afterthought. Rather than operating in silos, organizations should integrate sourcing and procurement into the process early to source new or different materials needed. It’s also important to get manufacturing engaged before launch to help plan how and where to produce new products. And by involving logistics from the start, organizations can think through how to handle inbound and outbound transportation for new products and be prepared to avoid or reduce the potential of backlogs for customers.

The integration of innovation into supply chain and otherwise, can clearly bolster a company’s resilience. To make innovation central to organizational culture, leaders must make it a deliberate and strategic priority for the business.

Using open innovation to support resilience

Many supply chains have had to adjust to the last 18 months by adopting new and innovative ways of conducting business and meeting the changing needs of customers. The need for innovation in supply chain was already apparent when APQC conducted its annual of supply chain priorities survey at the beginning of 2021. In it, 71%

of supply chain professionals said that innovation would be a top area of focus for their organizations in the coming year.

These professionals indicated that operational and process innovation was a priority for the year (see Figure 3). Product and service innovation had 10% fewer professionals indicating that it was a top focus area for the year.

Although the supply chain can play a key role in product development, organizations should think of innovation beyond the creation of products and services. To remain competitive, they need to reimagine their operations and processes to adjust to permanent changes and make themselves more resilient to future disruptions. They must also recognize the importance of supporting a culture of collaboration.

Open innovation provides an opportunity for the supply chain to foster collaboration and leverage external relationships to source ideas. From an operations and process standpoint, it can help companies get work done more efficiently at a lower cost. By increasing internal collaboration and work with external partners, organizations can often generate more and better ideas.

APQC recommends that organizations adopting open innovation do so in a strategic, intentional way. Innovation for its own sake and without structure can lead to changes that do not stick. Organizations must ensure that there are identified roles, processes and measures for continuous improvement. However, leaders must balance this with the flexibility to evaluate and eliminate barriers that are hindering the innovation effort.

What open innovation can look like has changed in the age of COVID-19. Greater access to online communication tools has provided another way for internal functions to collaborate. Yet there is still a benefit to proximity. Companies can provide in-person opportunities for internal collaboration once it is safe. They can also use geographical proximity to partners to support the sharing of mutually beneficial ideas.

Regardless of an organization’s size or industry, it has most likely had to innovate during the pandemic. To remain competitive through future disruptions and to harness the power of innovation to improve operations, organizations and their supply chains should be intentional about how they can encourage internal idea sharing and leverage external relationships.

About APQC

APQC helps organizations work smarter, faster and with greater confidence. It is the world’s foremost authority in benchmarking, best practices, process and performance improvement, and knowledge management. APQC’s unique structure as a member-based nonprofit makes it a differentiator in the marketplace. APQC partners with more than 500 member organizations worldwide in all industries. With more than 40 years of experience, APQC remains the world’s leader in transforming organizations. Visit us at apqc.org and learn how you can make best practices your practices.

SC

MR

Latest Supply Chain News

- Few executives believe their supply chains can respond quickly to disruptions

- Technology’s role in mending supply chain fragility after recent disruptions

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- More News

Latest Podcast

Explore

Explore

Procurement & Sourcing News

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- There is still work to do to achieve supply chain stability

- Blooming success: The vital role of S&OE in nurturing global supply chains

- How one small part held up shipments of thousands of autos

- More Procurement & Sourcing

Latest Procurement & Sourcing Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks