In today’s rapidly evolving customer and business landscape, supply chains play a crucial role in the streamlined flow of goods and services from manufacturers to end consumers. However, the complexity of global supply chains, coupled with increasing customer expectations and market dynamics, present significant challenges for businesses. Traditionally, supply chain management execution relied on manual processes and rule-based systems. The preponderance of data and its value had led to companies turning to artificial intelligence (AI) to transform their supply chain operations. While AI has applications across the supply chain spectrum, this article highlights its role in two pivotal end-to-end use cases, namely network strategy and demand - supply matching.

Supply chain network strategy

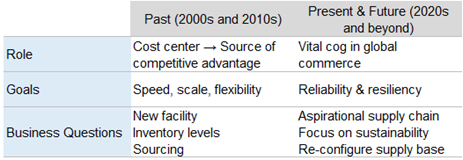

Network strategy refers to the overall plan and design of a company’s supply chain network encompassing the physical infrastructure, facilities, distribution channels, product flow, and relationships with suppliers and customers. It aims to create a network that aligns supply chain strategy with the organization’s business objectives. The following table outlines the evolution of network strategy over the past couple of decades.

Network strategy decisions are a collaborative exercise between operations, finance, and strategy, and result in substantial CAPEX investments. The group makes a largely experiential recommendation based on a projected growth forecast and a cost-benefit summary for signoff by a committee. While this approach is feasible, it tends to rely on intuition rather than rigorous analysis and fails to consider alternative options holistically. Balancing conflicting objectives such as maximizing profit, minimizing transit time, reducing carbon emissions, and improving customer experience, is challenging to model using tools like Excel. Additionally, modern supply chains need to shift from reacting to disruptions to preparing for one, which requires extensive scenario planning. As supply chains become global value chains focused on customer value, decisions made in one part of the network can have system-wide impact.

Network design technology leverages AI and optimization by ingesting vast amounts of data and configuring real-world constraints and flows. The user interface built for network design democratizes and accelerates the model-building process (digital representation of the current network), and enables visualization of the network. The ability to run multiple what-if scenarios is a game changer in evaluating the effect of decisions based on interacting priorities. Functionality for multi-period planning allows for the comparison of the existing network to the desired network, but also provides step-wise direction on achieving the outcomes.

Network design technology enables integration and modeling of end-to-end operational and financial data of a global supply chain. Also known as site selection, greenfield and brownfield analysis drive decisions on synergistic transformation of the physical assets (facilities). The ingestion, integration and interpretation of network-wide costs facilitates globally optimized decisions with the associated cost-benefit trade-off. In an era of complex and constrained sourcing dynamics, simulating the business impact of procurement decisions yields the trifecta of strategic alignment, cost savings, and resilience. For organizations undergoing mergers, finding synergy when combining existing networks can be made data-driven and deliberate with modeling capabilities of network design technology.

The size and complexity of global supply chains often present challenges when it comes to flexibility and adaptability. Architecting a data-driven blueprint for its continuous evolution, driven by market dynamics, has the potential to revolutionize the role of a supply chain. With the need to plan for, instead of reacting to, a disruption, scenario modeling potential risks, internal and external helps establish robust SOPs. This, in turn, ensures continuity and resilience within the supply chain allowing companies to respond swiftly and effectively to challenges. Optimizing the flow of products enables alignment of production, inventory, and distribution processes based on a comprehensive understanding of customer demand patterns and market trends. In addition to optimizing for cost, service, and capital, the potential for minimizing the carbon footprint will be a pivotal outcome in the future.

A pertinent characteristic of contemporary network design requires the in-house teams to identify new scenarios that involve an element of prognostication and foresight. In the near future, path-breaking innovation propelled by Gen AI will overcome this limitation by generating relevant alerts for their company, their network, and their specific objectives while analyzing the impact of an alert to the existing network. This will automate the scenario generation process, adding significant value to the outcomes of network design.

“Supply chains of the future will need to adapt on both a strategic and tactical level to ensure business continuity. Our SC Navigator Network Design solution enables supply chain teams to evolve from being reactive to proactive. At AIMMS, we believe AI will play a ‘front and center’ role in analyzing threats and notifying key stakeholders in real-time thus adding significant value to how companies run Network Design scenarios.”

- Zoe Kokje Schouten, business director of supply chain solutions at AIMMS

Demand-supply matching

Demand forecasting poses several challenges when considering various business rules and right-sizing inventory. First, incorporating complex business rules into forecasting models can be difficult. Many businesses have specific rules regarding promotions, discounts, seasonal fluctuations, and market trends that need to be taken into account. Aligning these rules with accurate demand forecasts requires sophisticated modeling techniques and a deep understanding of the business dynamics. This is especially crucial for right-sizing inventory, as overestimating or underestimating demand can lead to costly inventory imbalances. Excessive inventory can tie up valuable resources and result in increased carrying costs, while insufficient inventory can lead to stockouts, missed sales opportunities, and dissatisfied customers

Second, demand forecasting often involves dealing with large amounts of data from multiple sources, such as sales history, customer behavior, and market indicators. Integrating and analyzing this diverse data can be a complex task, notably when the data quality is inconsistent or incomplete. Ensuring data accuracy and reliability is crucial for obtaining reliable forecasts, which is essential for determining the optimal inventory levels.

Last, managing demand variability and uncertainty is a constant challenge. Unexpected events, such as supply chain disruptions or sudden shifts in consumer behavior, can significantly impact demand forecasts and subsequently affect inventory needs. By incorporating risk assessment and scenario planning into the forecasting process, businesses can better anticipate and prepare for such uncertainties, allowing for more effective right-sizing of inventory. Overcoming these challenges requires a combination of advanced analytics, robust data management systems, domain expertise, and effective collaboration between different departments within an organization.

AI-powered demand planning propels algorithmic and technological advances to address these challenges. AI-based forecasting can handle complex and comprehensive sets of business rules with greater efficiency. Machine learning algorithms learn patterns from vast amounts of data and adapt in real time while natural language processing models automate the extraction of business rules from contracts and reports to improve the forecasting process. The slew of data from various processes influencing demand planning can be ingested, integrated, and interpreted by intelligent workflows. The automated data quality checks and cleansing procedures ensure consistency and reliability, resulting in trustworthy forecasts. Effective demand planning thrives at the convergence of forecast precision and invaluable human judgment, culminating in data-driven insights and strategic decisions. By distilling incoming data for real-time analytics and visualization of demand fluctuations and related drivers, demand planners gain a bird’s-eye view of essential levers to optimize decision-making. This proactive approach empowers them to make informed adjustments, ensuring agile and efficient demand planning for enhanced business outcomes.

AI-driven demand planning capabilities enable businesses to effectively manage demand variability and uncertainty through scenario planning and risk assessment tools. Leveraging AI algorithms, these capabilities can simulate multiple scenarios based on potential disruptions or market changes, providing valuable insights into inventory requirements under different circumstances. Demand collaboration platforms streamline interdepartmental collaboration by providing a centralized system with real-time access to demand forecasts, inventory data, and market insights for all stakeholders. Through intelligent data sharing and seamless communication, this capability fosters a cohesive and data-driven approach to demand planning and inventory management, promoting cross-functional alignment and enhancing overall operational efficiency.

By harnessing these capabilities, businesses can overcome the challenges posed by demand forecasting and right-sizing inventory. Advanced AI-powered forecasting models provide accurate predictions, while robust data integration and quality management ensure reliable data inputs. Real-time analytics and visualization tools aid in spotting demand fluctuations promptly. Scenario planning and risk assessment capabilities help in preparing for uncertainties, and collaborative demand collaboration platforms enhance cross-functional cooperation. Embracing these capabilities enables businesses to optimize inventory levels, minimize carrying costs, prevent stockouts, and ultimately deliver better customer satisfaction in today’s dynamic business landscape.

“We have witnessed how AI-led forecasting solutions have been a game-changer for my clients, driving remarkable cost savings and increased efficiency. Embracing best-in-class technology has positioned them as industry leaders, unlocking a world of data-driven possibilities for growth and profitability.” - Raul Jurado, director of customer success at Asper.ai.

About the author:

Ashok Viswanathan is the director of supply chain analytics at Best Buy and an adjunct professor at Rutgers University where he teaches supply chain digital transformation. He can be reached at [email protected].

SC

MR

More Inventory Management

- April manufacturing output slides after growing in March

- World Trade Centers offers a helping hand to create resilient, interconnected supply chains

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How S&OP provides the answer to in-demand products

- Shining light on procurement’s dark purchases problem

- ISM reports that services sector sees continued growth in March

- More Inventory Management

Latest Podcast

Explore

Explore

Topics

Procurement & Sourcing News

- Despite American political environment, global geopolitical risks may be easing

- April manufacturing output slides after growing in March

- World Trade Centers offers a helping hand to create resilient, interconnected supply chains

- Bridging the ESG gap in supply chain management: From ambition to action

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- More Procurement & Sourcing

Latest Procurement & Sourcing Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks