Compliance to procurement policies and contracts is critical to driving the benefits of sourcing work to the bottom line and achieving year-over-year improvement goals. But in some industries compliance is mainly a matter of protecting against audits or following governmental and other regulations. To help discover how companies are approaching procurement-related compliance, A.T. Kearney undertook a benchmarking study of 15 Global 500 companies. The survey instrument was supplemented by follow-up interviews with executives that helped to provide context to the responses.

Procurement compliance occurs both within and outside the company. Internally, companies to varying degrees implement programs geared toward enforcing compliance to the sourcing process, the buying process, contracts, and preferred suppliers. Supplier invoices are also monitored to ensure that they hold true to contracted prices.

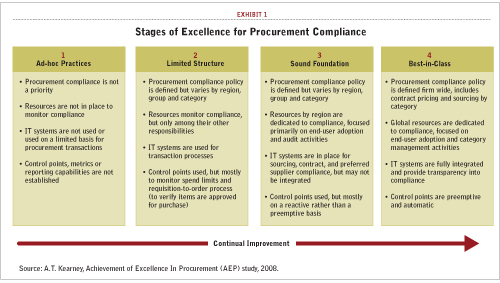

While survey respondents were classified along four stages of excellence for sourcing and procurement compliance (see Exhibit 1), not every company will strive to reach the highest stage. Instead, each should create pragmatic programs that are right for the organization in terms of need and ability to invest in compliance. Companies with center-led or centralized procurement functions tended to place in Stages 3 and 4, as did those in the consumer packaged goods and pharmaceutical industries.

Relative to the amount of effort required, study participants indicated that demand management and compliance to contracts brought the highest anticipated return among eight different types of procurement programs. Strategic sourcing and process compliance were also highly regarded in terms of anticipated benefit. Companies will not simply go after the highest potential benefit first; where a company is in its evolution, how it views cost avoidance and the importance it places on opportunity cost are a few of the factors that lead companies down different paths.

Not surprisingly, companies generally expect all employees affected by compliance guidelines (internal end users and procurement staff) to follow them—and most also expect suppliers and internal business partners to do so as well.

The survey results indicated that the survey participants have put their strongest efforts into ensuring compliance to the sourcing and buying processes, with compliance to contract pricing by supplier and compliance to contracts and preferred suppliers receiving less attention. Those that are achieving compliance to preferred suppliers are doing so through the use of technology tools that force compliance. While most companies emphasize the need to comply with the sourcing process, they also typically establish a spend threshold for engaging their limited sourcing resources in order to maximize return on investment. Most roundtable participants noted that their own companies employ computerized training modules to teach employees about compliance.

Resource constraints and a lack of tools for end users were cited as the two greatest challenges around driving compliance. Overcoming these challenges may well push many Stage 3 organizations up to Stage 4—Best in Class.

On average, companies dedicate fewer than three total FTEs to deploying and managing compliance efforts. Category managers most frequently have this among their duties, which is not surprising in light of the skin they have in the game around actual savings realization. Simplified contracts can make compliance easier. Third-party services can be used to monitor supplier compliance to contract terms; some work on a contingency basis that awards them some percentage of any monies rebated by suppliers as a result of their work.

Compliance tools are generally reactive, such as after-the-fact reporting that shows spend outside of the preferred suppliers. Less than half of the companies in the study have successfully implemented tools to manage compliance. While few companies have gone this route, one way to proactively enforce compliance is to have a requisitioner verify whether a vendor is a preferred supplier before a purchase is approved.

Because non-compliance typically occurs when an employee chooses to take a short-term action to benefit his or her particular function or business unit, the most common repercussion is reporting of the incident to senior management outside of procurement in order to reinforce the fact that compliance is about the mutual benefit of the entire enterprise.

Survey respondents indicated that control points and metrics are most frequently employed to drive compliance to procurement. Stage 3 and 4 companies typically use control points instead of monitoring. Some executives feel that human feedback regarding compliance brings a greater influence on people than simply having a technology-driven purchasing system deny an action.

Ultimately it is up to each company to reexamine its compliance program to verify whether it fits with corporate goals. Efforts need to be focused to ensure that they are driving value. Programs need to be assessed to determine their value add; those that are retained or implemented need to be properly marketed to gain buy-in from internal stakeholders. Policies and tools that promote proactive end user compliance by all employees, not just procurement and sourcing staff, drive superior compliance.

SC

MR

Latest Supply Chain News

- Strategic cost savings differ from cutting costs

- Planning fatigue may be settling in

- Inflation, economic worries among top supply chain concerns for SMBs

- April Services PMI declines following 15 months of growth, reports ISM

- Attacking stubborn COGS inflation with Digital Design-and-Source-to-Value

- More News

Latest Podcast

Explore

Explore

Topics

Latest Supply Chain News

- Strategic cost savings differ from cutting costs

- Planning fatigue may be settling in

- Inflation, economic worries among top supply chain concerns for SMBs

- April Services PMI declines following 15 months of growth, reports ISM

- Attacking stubborn COGS inflation with Digital Design-and-Source-to-Value

- Despite American political environment, global geopolitical risks may be easing

- More latest news

Latest Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks