Over the years I have been fortunate to collect a wealth of both academic knowledge and professional experience in sourcing management. I have witnessed how the perception of procurement contribution to business objectives has evolved in the eyes of senior leaders. In this article I would like to examine how organizations can realize the benefits of effective execution of purchasing strategies in their P&Ls.

If we consider the organization principally in systems terms, then we have a structure that demands inputs of goods and services from external sources to convert them into some product format to sell and generate value from the performance of these activities. We can observe from this simplified organizational structure that purchasing is the function serving as the guardian of inputs that hold a principal position in the corporate structure. This loose grouping of people we often call purchasers or procurement officers are determinants of both end-product specification and how much revenue is being generated from the value added through the transition of inputs into final outputs.

The scope of purchasing's contribution to corporate performance has been gradually growing over the past two to three decades. Conversely, the perception of the contribution that the function makes remains variable (1) and incomplete across all production and servicing departments.

Nevertheless, if we consider that the cost of purchased goods and services typically amounts to between 50% and 90% (2) of a company's overall expenditures, purchasing does become a key contributor to the net profit margin of the organization. To define the scope of the procurement function, purchasing is explained as "obtaining from external sources all goods, services, capabilities, and knowledge that are necessary for running, maintaining, and managing the company's primary and support activities at the most favorable cost conditions."

Undoubtedly, the procurement of materials is not as vital to some companies as it is to others. The authors of Purchasing Principles & Management (3) state that the average manufacturing company spends well over half its income on materials and services, and in some extreme cases the figure approaches 90%.

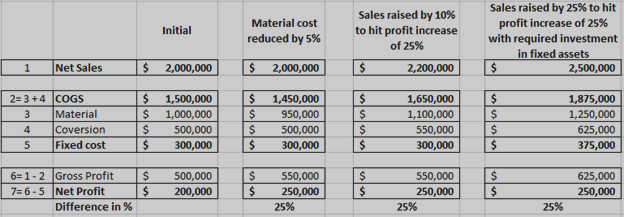

Given that average, let's take an example, suppose that a company has total annual sales of $2 million and that it makes a profit of 10%, equal to $200,000.

1. The company spends 50% of its sales on materials and services and can achieve a saving of 5% on its material costs. The result of efficiency with regard to the company's management of materials can then be shown in the following way:

- $2M sales @ 10% profit = $200,000

- On $1M spend a 5% saving in materials costs = $50,000

- Total profit of $250,000

2. Now, if the savings in material costs were not achieved, and assuming you can increase your sales output without any investment in your production facilities (fixed asset cost remain unchanged), it would need to increase sales by $200,000, in other words by 10%.

3. Another scenario is that material costs were not achieved, however the profit ratio was maintained at 10% meaning that investment in fixed assets (e.g. production equipment) was required. This would require sales to increase by $500,000, or by 25%.

As you can see the validity of this illustration depends upon several factors. However, it is undeniable that the financial impact of purchasing effectiveness and efficiency is very explicit. Crucially, every cent saved by purchasing is a cent added to the bottom-line profit. In contrast to the sales department, where every $1 of additional sales brings with it perhaps 90 cents of extra costs, the net impact on profit from procurement is only 10 cents (assuming sales @ 10% profit). This is not to say that boosting sales are in any sense less important than sourcing from the right suppliers. My intention here is purely to explain how effective management of sourcing activities can deliver lasting P&L impact and push businesses to a position of market leadership.

(1) T. Metty, R. Harlan, Q. Samelson, T. Moore, T. Morris, R. Sorensen, Reinventing the Supplier Negotiation Process at Motorola, Interfaces, Vol. 35, No. 1, January–February 2005, Schaumburg, Illinois, 2005

(2) M Day, Handbook of Purchasing Management, Gower Publishing Company, Aldershot 2002

(3) P. Baily, D. Farmer, D. Jessop, D. Jones, Purchasing Principles & Management, Pearson Education Limited, Essex 1998

About the author:

Michal Cukier is a seasoned procurement leader, with 13+ years of progressive international supply chain experience in both established and emerging markets from global organizations (Reckitt Benckiser, Philips Electronics). He has spent the last 10 years working in consumer health division of major CPG company where he developed in-depth knowledge and expertise in building robust procurement strategies for direct material spend categories with focus on efficacious sourcing process, supply assurance, cost, and quality.

SC

MR

More Supply Chain Management

- Three frameworks for creative problem-solving in supply chain

- Mitigating geopolitical uncertainty: 4 essential tactics for industrial CSCOs

- Supply chain strategy for medical devices: A Q&A with industry expert Sanjay Gupta

- Election-year effect: The scenarios that could impact the supply chain

- Commodity or customization: Is next or same day a necessary brand strategy?

- Understanding organized labor’s impact on our supply chain

- More Supply Chain Management

Latest Podcast

Explore

Explore

Topics

Procurement & Sourcing News

- Three frameworks for creative problem-solving in supply chain

- Mitigating geopolitical uncertainty: 4 essential tactics for industrial CSCOs

- Supply chain strategy for medical devices: A Q&A with industry expert Sanjay Gupta

- Inventory Management and the Supply Chain: Outlook 2025

- How technological innovation is paving the way for a carbon-free future in logistics and supply chains

- Parcel shipping spend: The untamed holdout in today’s supply chains

- More Procurement & Sourcing

Latest Procurement & Sourcing Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks