Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

January-February 2012

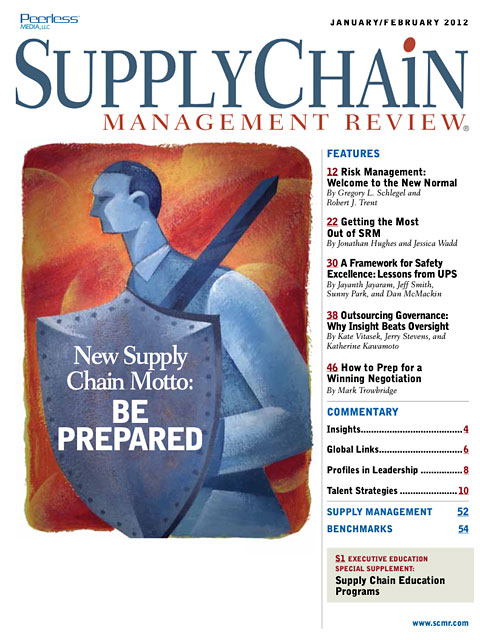

The potential risk of supply chain disruption has never been greater. In fact, it’s become the new normal, say authors and educators Robert Trent and Greg Schlegel. The problem for many companies is that they are ill prepared to handle a disruption should one occur. This article argues for a new set of risk management techniques in a world where heightened supply chain risk has become a fact of business life. Browse this issue archive.Need Help? Contact customer service 847-559-7581 More options

Hurricanes, earthquakes, tsunamis, tornadoes, and billowing ash from obscure volcanoes all have some things in common. Over the last several years each has been featured prominently in the news. And each has had the inevitable effect of disrupting global supply chains. Yet these kinds of disruptions were not on the minds of Astella Pharma executives on June 17, 2009. On that night thieves stole a trailer containing $10 million of the company’s pharmaceutical products from a truck stop in Tennessee. What followed was a harsh lesson in the realities of supply chain risk.

Once the final tallies were made, the actual cost of the stolen product was just a fraction of the losses eventually suffered by Astella. Acting on advice from the U.S. Food & Drug Administration, the company quickly contacted every party in its supply chain, ranging from wholesalers to hospitals, warning them of the stolen drugs. Then, as a preventive measure, Astella withdrew from the marketplace all drugs with the same lot numbers as those that were stolen. Some of the stolen pharmaceuticals required strict climate control (something the thieves were likely not too concerned about), thereby necessitating the return of all product with those lot numbers. The $10 million theft eventually cost the company $47 million, a figure equivalent to 10 percent of its North American sales for that quarter. Welcome to the world of supply chain risk—a world where sometimes the only thing we should expect is the unexpected.

This article argues that the risk management techniques currently in place, most of which are put forth with the best of intentions, may not be sufficient to allow supply chain organizations to attain risk management excellence in a dangerous world. An innovative set of approaches is needed in a world where heightened risk represents the new normal.

|

This complete article is available to subscribers

only. Click on Log In Now at the top of this article for full access. Or, Start your PLUS+ subscription for instant access. |

Not ready to subscribe, but need this article?

Buy the complete article now. Only $20.00. Instant PDF Download.

Access the complete issue of Supply Chain Management Review magazine featuring

this article including every word, chart and table exactly as it appeared in the magazine.

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

January-February 2012

The potential risk of supply chain disruption has never been greater. In fact, it’s become the new normal, say authors and educators Robert Trent and Greg Schlegel. The problem for many companies is that they are… Browse this issue archive. Download a PDF file of the January-February 2012 issue. |

Download Article PDF |

Hurricanes, earthquakes, tsunamis, tornadoes, and billowing ash from obscure volcanoes all have some things in common. Over the last several years each has been featured prominently in the news. And each has had the inevitable effect of disrupting global supply chains. Yet these kinds of disruptions were not on the minds of Astella Pharma executives on June 17, 2009. On that night thieves stole a trailer containing $10 million of the company’s pharmaceutical products from a truck stop in Tennessee. What followed was a harsh lesson in the realities of supply chain risk.

Once the final tallies were made, the actual cost of the stolen product was just a fraction of the losses eventually suffered by Astella. Acting on advice from the U.S. Food & Drug Administration, the company quickly contacted every party in its supply chain, ranging from wholesalers to hospitals, warning them of the stolen drugs. Then, as a preventive measure, Astella withdrew from the marketplace all drugs with the same lot numbers as those that were stolen. Some of the stolen pharmaceuticals required strict climate control (something the thieves were likely not too concerned about), thereby necessitating the return of all product with those lot numbers. The $10 million theft eventually cost the company $47 million, a figure equivalent to 10 percent of its North American sales for that quarter. Welcome to the world of supply chain risk—a world where sometimes the only thing we should expect is the unexpected.

This article argues that the risk management techniques currently in place, most of which are put forth with the best of intentions, may not be sufficient to allow supply chain organizations to attain risk management excellence in a dangerous world. An innovative set of approaches is needed in a world where heightened risk represents the new normal.

|

SUBSCRIBERS: Click here to download PDF of the full article. |

SC

MR

Latest Supply Chain News

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- Tips for CIOs to overcome technology talent acquisition troubles

- More News

Latest Podcast

Explore

Explore

Latest Supply Chain News

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- Tips for CIOs to overcome technology talent acquisition troubles

- There is still work to do to achieve supply chain stability

- More latest news

Latest Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks