Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

December 2018

It’s December and time once again for our annual Executive Guide to Supply Chain Resources. This is a comprehensive guide to services, products and educational opportunities targeted specifically to supply chain professionals. As with years past, we’re also featuring several articles we trust will offer food for thought in your supply chain in the coming year. Browse this issue archive.Need Help? Contact customer service 847-559-7581 More options

Effective demand management is critical to the financial performance and health of an organization. Demand management is boundary spanning and, as such, needs to be independent of the functional management organization. When we refer to demand management, we are referring to every functional group within the organization contributing to and relying on managing demand. Digitization and digitalization offer the promise of digital collaboration across functional silos and organizational boundaries without significant manual interaction. However, to be successful companies must overcome the common pitfalls and archetypes that have evolved from decades of insufficient and siloed enterprise demand planning and management. Let’s take a look at the four most common pitfalls of demand planning.

The Problem: The traditional supply chain view is linear and disconnected Pitfall No. 1: Lack of an organizational commitment to improved demand planning

• Organizational culture has been conditioned to the “forecast is always wrong.”

• Lack of executive commitment to integrated demand/supply planning:

– demand planning resides in functional silos with a bias to functional metrics; and

– demand planning led by middle managers supported by junior analysts.

• Operational demand planning is supply chain focused and forecast oriented.

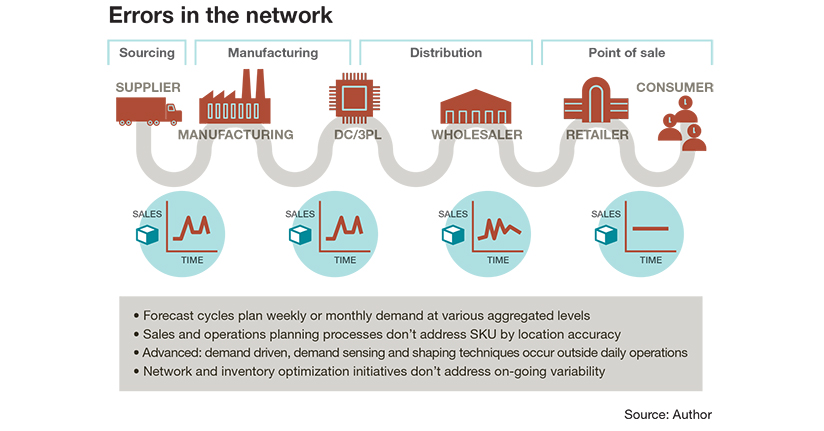

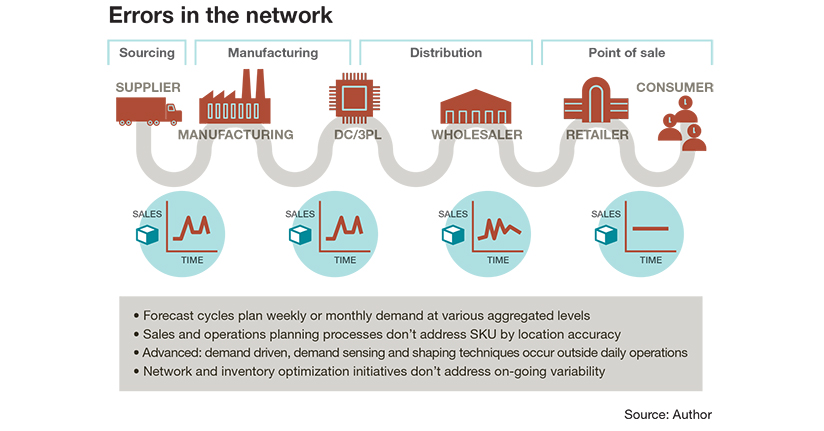

We traditionally view the supply chain as a chain of sequential links each with behavioral attributes that act separately and together to cause demand variation from historical performance. This has been widely characterized as the bullwhip effect. As demand variations are communicated sequentially through the supply chain there are time delays and amplification of the signal variations that cause error to propagate the network (see Figure 1).

Effective demand management is critical to the financial performance and health of an organization. Demand management is boundary spanning and, as such, needs to be independent of the functional management organization. When we refer to demand management, we are referring to every functional group within the organization contributing to and relying on managing demand. Digitization and digitalization offer the promise of digital collaboration across functional silos and organizational boundaries without significant manual interaction. However, to be successful companies must overcome the common pitfalls and archetypes that have evolved from decades of insufficient and siloed enterprise demand planning and management. Let’s take a look at the four most common pitfalls of demand planning.

The Problem: The traditional supply chain view is linear and disconnected Pitfall No. 1: Lack of an organizational commitment to improved demand planning

- Organizational culture has been conditioned to the “forecast is always wrong.”

- Lack of executive commitment to integrated demand/supply planning: -demand planning resides in functional silos with a bias to functional metrics; and -demand planning led by middle managers supported by junior analysts.

- Operational demand planning is supply chain focused and forecast oriented.

We traditionally view the supply chain as a chain of sequential links each with behavioral attributes that act separately and together to cause demand variation from historical performance. This has been widely characterized as the bullwhip effect. As demand variations are communicated sequentially through the supply chain there are time delays and amplification of the signal variations that cause error to propagate the network.

This complete article is available to subscribers only.

Log in now for full access or start your PLUS+ subscription for instant access.

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

December 2018

It’s December and time once again for our annual Executive Guide to Supply Chain Resources. This is a comprehensive guide to services, products and educational opportunities targeted specifically to supply chain… Browse this issue archive. Access your online digital edition. Download a PDF file of the December 2018 issue.Effective demand management is critical to the financial performance and health of an organization. Demand management is boundary spanning and, as such, needs to be independent of the functional management organization. When we refer to demand management, we are referring to every functional group within the organization contributing to and relying on managing demand. Digitization and digitalization offer the promise of digital collaboration across functional silos and organizational boundaries without significant manual interaction. However, to be successful companies must overcome the common pitfalls and archetypes that have evolved from decades of insufficient and siloed enterprise demand planning and management. Let's take a look at the four most common pitfalls of demand planning.

The Problem: The traditional supply chain view is linear and disconnected Pitfall No. 1: Lack of an organizational commitment to improved demand planning

- Organizational culture has been conditioned to the “forecast is always wrong.”

- Lack of executive commitment to integrated demand/supply planning: – demand planning resides in functional silos with a bias to functional metrics; and – demand planning led by middle managers supported by junior analysts.

- Operational demand planning is supply chain focused and forecast oriented.

We traditionally view the supply chain as a chain of sequential links each with behavioral attributes that act separately and together to cause demand variation from historical performance. This has been widely characterized as the bullwhip effect. As demand variations are communicated sequentially through the supply chain there are time delays and amplification of the signal variations that cause error to propagate the network (see Figure 1).

Effective demand management is critical to the financial performance and health of an organization. Demand management is boundary spanning and, as such, needs to be independent of the functional management organization. When we refer to demand management, we are referring to every functional group within the organization contributing to and relying on managing demand. Digitization and digitalization offer the promise of digital collaboration across functional silos and organizational boundaries without significant manual interaction. However, to be successful companies must overcome the common pitfalls and archetypes that have evolved from decades of insufficient and siloed enterprise demand planning and management. Let's take a look at the four most common pitfalls of demand planning.

The Problem: The traditional supply chain view is linear and disconnected Pitfall No. 1: Lack of an organizational commitment to improved demand planning

- Organizational culture has been conditioned to the “forecast is always wrong.”

- Lack of executive commitment to integrated demand/supply planning: -demand planning resides in functional silos with a bias to functional metrics; and -demand planning led by middle managers supported by junior analysts.

- Operational demand planning is supply chain focused and forecast oriented.

We traditionally view the supply chain as a chain of sequential links each with behavioral attributes that act separately and together to cause demand variation from historical performance. This has been widely characterized as the bullwhip effect. As demand variations are communicated sequentially through the supply chain there are time delays and amplification of the signal variations that cause error to propagate the network.

SUBSCRIBERS: Click here to download PDF of the full article.

SUBSCRIBERS: Click here to download PDF of the full article.

SC

MR

Latest Supply Chain News

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- More News

Latest Podcast

Explore

Explore

Business Management News

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- Tips for CIOs to overcome technology talent acquisition troubles

- There is still work to do to achieve supply chain stability

- More Business Management

Latest Business Management Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks