Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

January-February 2023

It feels like a normal holiday season. ”That was the report I got from the VP of global distribution at one of the country’s best known retail brands on the Monday before Black Friday. He added that the last time he felt that way was November of 2019. One of the perks of this job is that I get to talk to a lot of supply chain executives. In my conversations over the last year, I’ve learned two things. Operations, which was perhaps hardest hit at the start of the pandemic, has learned to operate in this new environment. Sure, there are still hiccups caused by absenteeism and inventory shortages. But those are situational—give them supply and… Browse this issue archive.Need Help? Contact customer service 847-559-7581 More options

This is a revised column from one that Dr. Chaman Jain, the editor of the Journal of Business Forecasting (JBF), recently asked me to write. It discussed the relationship between strategic and operational planning. He asked me: Is there any change in the relationship between the two? If so, what changes have occurred and why?

The short answer is that operational planning under uncertainty (vis-a-vis risk), is similar to strategic planning despite the short planning horizons. That is because, in my view, both involve planning under uncertainty and both should use a scenario planning approach.

In my column in the July/August 2022 issue of SCMR1, I proposed that operational planning under uncertainty be called “quick response (QR).” The response is considered “quick” because uncertainties force managers to (uncomfortably) make fast decisions with minimal or no information about the future—for example, about demand and even supply, as we all learned during the pandemic.

Hierarchy planning framework

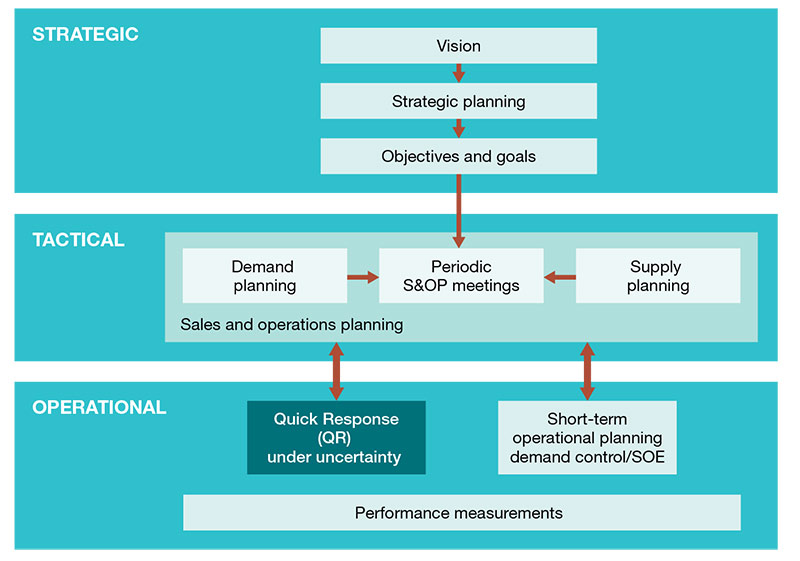

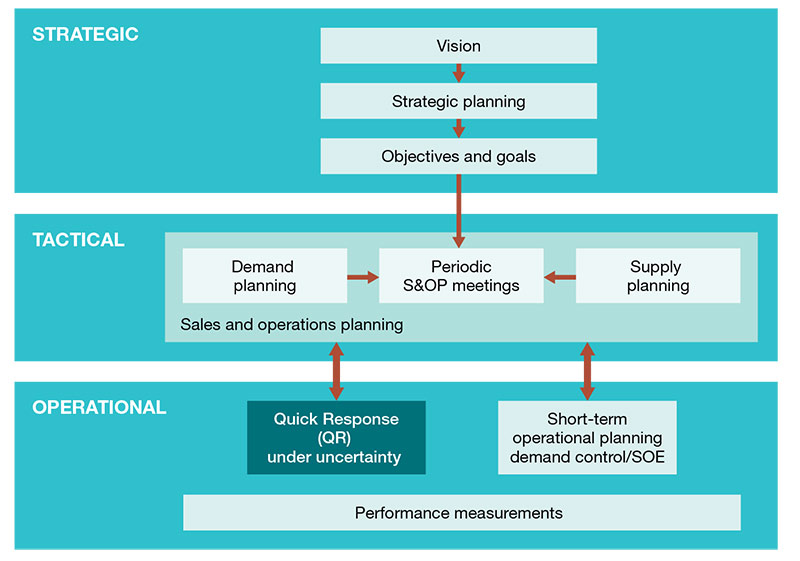

In that column, I discussed a hierarchy demand-supply planning framework (see Figure 1) that I have written about in the past. I included the following three levels of planning processes based on the length of their planning horizons.

- Strategic planning. This looks far out into the future and has a long planning horizon with “time-buckets” in terms of years (in contrast to months and weeks). Strategic planning involves the development of a road map to the future and typically has a planning horizon of from three years to five years; and even longer in capital-intensive industries.

- Sales and operations planning (S&OP). This medium-term tactical planning process typically has a planning horizon from six months up to two years, and uses time-buckets of months and weeks.

- Operational planning. These short-term planning processes might have planning horizons as short as a single day (with time-buckets of hours) up to three months (with time-buckets of days, weeks and months). QR is planning under uncertainty, while sales and operational execution (SOE) or demand control are under risk, because history can be used as a guide.

Strategic planning under this framework is predicated on a company believing that it will be around for at least as long as the longest planning horizon under consideration. A length for which forecasting is virtually useless to support the development of concrete strategic plans. A business environment can significantly change over this timeframe. And this length of time also needs to assume the future is fraught with uncertainties. Instead of forecasting a future, strategic planning needs to consider potential futures, termed scenarios.

In this regard, in “Strategic planning under uncertainty: Long-term muddling-through,”2 I described a strategic planning approach developed during the MIT Supply Chain 2020 Project that I launched in 2005. The approach in that column was positioned as an illustration of a typical strategy planning process, in contrast to shorter-term planning processes such as S&OP and SOE. The latter processes involve planning under risk, and thus assume that managers can estimate sundry probabilities using historical demand and supply data.

Figure 1: Hierarchy demand-supply planning framework

(Including Quick Response (QR) as a temporary process to evolve from chaos to stability)

Source: Author

A strategic planning process begins with developing scenarios of futures that are likely to occur without the probabilities of their occurrences. A typical set might include: a pessimistic, a most likely and an optimistic scenario. In that column, I introduced a scenario planning decision making framework for making decisions and updating plans over time as the future unfolds. It discusses how, by assembling data over time, planning becomes under risk because future possibilities become estimable. The strategy typically does not change over time because it is aimed toward achieving a

specific future vision of the company.

I suggested that this type of “muddling through” approach might also be applied to the QR process, aimed at mitigating the impacts of natural disasters, pandemics, earthquakes, hurricanes and wildfires. It might also apply to other sporadic events, for which the probability of an event and/or its severity would be inestimable.

QR considers flexible short-term strategies

A dictionary defines strategy as:

“…a word that was first used by the military. It comes from an ancient Greek word for the general officer commanding all the armed forces of a state. A strategy is a long-term plan on what to do to achieve a certain goal. When talking about the near future, people often use the word tactics. Today, the word “strategy” is in common use; people might talk about “business strategy,” for example. The distinction between strategy and tactics applies to any planning that might be done against an enemy or opponent. Strategy is what we broadly intend to do to reach our long-term goal or objective. Tactics is the detailed steps that are used as our progress is opposed by the opponent. For this reason, tactics are short-scale and flexible. Strategy, on the other hand, is changed as little as possible.”

Note that the above definition says strategy is changed as little as possible, while tactics are flexible. That is much like the strategic planning approach I described above. However, an approach for the QR process would assume that a strategy is being tested and would be revised if conditions on the ground show that it can no longer achieve its intended goal. The trouble with using strategic for only long-term planning is that “long” is a subjective term. For example, why plan five years out if your immediate survival is questionable?

My father-in-law was a wise man who lived into his mid-80s. I fondly remember him saying that at his age he shouldn’t buy green bananas. This was his version of a quote from Don Meyers, a famous basketball coach, who said: “When you get to be my age, you don’t buy green bananas because you may not be around to eat them.”

In my younger days, I made important decisions looking at the short-term as well as the long-term consequences of my actions, sometimes as far out as retirement. Now that I am in retirement, my current planning horizon has shortened to about seven years to 10 years at most.

At the beginning of the pandemic—an event that was about as uncertain as one can get—I came to the recognition that the major concern of forecasters and planners involved losing the ability to look back in time for guidance. From a demand perspective, every product looked like a new product being introduced into new, unknown and uncertain markets. Moreover, from a supply side, each supplier’s viability was at stake, and might go out of business.

Together these put a company at risk of going out of business as well. Essentially, the strategic, tactic and operational planning horizons were overlapping quite a bit. Long-term among them was likely just three months long, enough time to see whether a strategy is showing promise.

In “Decision making under uncertainty: A primer,”3 I discussed a hypothetical example of how an initial strategy to be tested might be decided upon using a scenario planning approach in the QR process. The process begins with estimating a payoff matrix that delineates the financial consequences for each strategy being considered under a set of possible future scenarios. However, unlike typical long-term scenario planning, the strategy might need to be changed often because the business environment would be dynamic and rapidly changing.

For this reason, I also proposed using short lifecycle forecasting for muddling through uncertainties, which was the title of another column.4 This forecasting method is used for forecasting demand during the launch of new and revised “seasonal” products. The approach starts with an

initial forecast of total demand for a product over a short lifecycle of time, and the forecast is constantly revised as demand data is collected, which could be month-to-month.

Thus, a simple answer to the first of Dr. Jain’s questions is that there is no change in the relationship between strategic and operational planning. The former is still long-term and latter still short-term.

His second question was: “If so, what changes have occurred and why?” I believe that the major change since the pandemic is the need for a new formal operational planning process under uncertainty that I’ve termed quick response. It’s not the same as SOE, which is planning under risk.

In addition, the strategic planning and QR processes are strategically focused. Therefore, both processes have to be directed by someone from the executive suite because the risks are too high vis-a-vis those taken during the SOE and S&OP processes. Executives are needed to decide whether to make high risk existential decisions, and not just whether to buy green bananas.

- “Revisiting quick response,” Supply Chain Management Review, Jul/Aug 2022

- “Strategic planning under uncertainty: Long-term muddling-through,” Supply Chain Management Review, Jul/Aug 2021

- “Decision making under uncertainty: A primer,” Supply Chain Management Review, May/Jun 2022

- “Short lifecycle (SLC) forecasting for ‘muddling-through’ uncertainties,” Supply Chain Management Review, Nov 2021

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

January-February 2023

It feels like a normal holiday season. ”That was the report I got from the VP of global distribution at one of the country’s best known retail brands on the Monday before Black Friday. He added that the last time… Browse this issue archive. Access your online digital edition. Download a PDF file of the January-February 2023 issue.This is a revised column from one that Dr. Chaman Jain, the editor of the Journal of Business Forecasting (JBF), recently asked me to write. It discussed the relationship between strategic and operational planning. He asked me: Is there any change in the relationship between the two? If so, what changes have occurred and why?

The short answer is that operational planning under uncertainty (vis-a-vis risk), is similar to strategic planning despite the short planning horizons. That is because, in my view, both involve planning under uncertainty and both should use a scenario planning approach.

In my column in the July/August 2022 issue of SCMR1, I proposed that operational planning under uncertainty be called “quick response (QR).” The response is considered “quick” because uncertainties force managers to (uncomfortably) make fast decisions with minimal or no information about the future—for example, about demand and even supply, as we all learned during the pandemic.

Hierarchy planning framework

In that column, I discussed a hierarchy demand-supply planning framework (see Figure 1) that I have written about in the past. I included the following three levels of planning processes based on the length of their planning horizons.

- Strategic planning. This looks far out into the future and has a long planning horizon with “time-buckets” in terms of years (in contrast to months and weeks). Strategic planning involves the development of a road map to the future and typically has a planning horizon of from three years to five years; and even longer in capital-intensive industries.

- Sales and operations planning (S&OP). This medium-term tactical planning process typically has a planning horizon from six months up to two years, and uses time-buckets of months and weeks.

- Operational planning. These short-term planning processes might have planning horizons as short as a single day (with time-buckets of hours) up to three months (with time-buckets of days, weeks and months). QR is planning under uncertainty, while sales and operational execution (SOE) or demand control are under risk, because history can be used as a guide.

Strategic planning under this framework is predicated on a company believing that it will be around for at least as long as the longest planning horizon under consideration. A length for which forecasting is virtually useless to support the development of concrete strategic plans. A business environment can significantly change over this timeframe. And this length of time also needs to assume the future is fraught with uncertainties. Instead of forecasting a future, strategic planning needs to consider potential futures, termed scenarios.

In this regard, in “Strategic planning under uncertainty: Long-term muddling-through,”2 I described a strategic planning approach developed during the MIT Supply Chain 2020 Project that I launched in 2005. The approach in that column was positioned as an illustration of a typical strategy planning process, in contrast to shorter-term planning processes such as S&OP and SOE. The latter processes involve planning under risk, and thus assume that managers can estimate sundry probabilities using historical demand and supply data.

Figure 1: Hierarchy demand-supply planning framework

(Including Quick Response (QR) as a temporary process to evolve from chaos to stability)

Source: Author

A strategic planning process begins with developing scenarios of futures that are likely to occur without the probabilities of their occurrences. A typical set might include: a pessimistic, a most likely and an optimistic scenario. In that column, I introduced a scenario planning decision making framework for making decisions and updating plans over time as the future unfolds. It discusses how, by assembling data over time, planning becomes under risk because future possibilities become estimable. The strategy typically does not change over time because it is aimed toward achieving a

specific future vision of the company.

I suggested that this type of “muddling through” approach might also be applied to the QR process, aimed at mitigating the impacts of natural disasters, pandemics, earthquakes, hurricanes and wildfires. It might also apply to other sporadic events, for which the probability of an event and/or its severity would be inestimable.

QR considers flexible short-term strategies

A dictionary defines strategy as:

“…a word that was first used by the military. It comes from an ancient Greek word for the general officer commanding all the armed forces of a state. A strategy is a long-term plan on what to do to achieve a certain goal. When talking about the near future, people often use the word tactics. Today, the word “strategy” is in common use; people might talk about “business strategy,” for example. The distinction between strategy and tactics applies to any planning that might be done against an enemy or opponent. Strategy is what we broadly intend to do to reach our long-term goal or objective. Tactics is the detailed steps that are used as our progress is opposed by the opponent. For this reason, tactics are short-scale and flexible. Strategy, on the other hand, is changed as little as possible.”

Note that the above definition says strategy is changed as little as possible, while tactics are flexible. That is much like the strategic planning approach I described above. However, an approach for the QR process would assume that a strategy is being tested and would be revised if conditions on the ground show that it can no longer achieve its intended goal. The trouble with using strategic for only long-term planning is that “long” is a subjective term. For example, why plan five years out if your immediate survival is questionable?

My father-in-law was a wise man who lived into his mid-80s. I fondly remember him saying that at his age he shouldn’t buy green bananas. This was his version of a quote from Don Meyers, a famous basketball coach, who said: “When you get to be my age, you don’t buy green bananas because you may not be around to eat them.”

In my younger days, I made important decisions looking at the short-term as well as the long-term consequences of my actions, sometimes as far out as retirement. Now that I am in retirement, my current planning horizon has shortened to about seven years to 10 years at most.

At the beginning of the pandemic—an event that was about as uncertain as one can get—I came to the recognition that the major concern of forecasters and planners involved losing the ability to look back in time for guidance. From a demand perspective, every product looked like a new product being introduced into new, unknown and uncertain markets. Moreover, from a supply side, each supplier’s viability was at stake, and might go out of business.

Together these put a company at risk of going out of business as well. Essentially, the strategic, tactic and operational planning horizons were overlapping quite a bit. Long-term among them was likely just three months long, enough time to see whether a strategy is showing promise.

In “Decision making under uncertainty: A primer,”3 I discussed a hypothetical example of how an initial strategy to be tested might be decided upon using a scenario planning approach in the QR process. The process begins with estimating a payoff matrix that delineates the financial consequences for each strategy being considered under a set of possible future scenarios. However, unlike typical long-term scenario planning, the strategy might need to be changed often because the business environment would be dynamic and rapidly changing.

For this reason, I also proposed using short lifecycle forecasting for muddling through uncertainties, which was the title of another column.4 This forecasting method is used for forecasting demand during the launch of new and revised “seasonal” products. The approach starts with an

initial forecast of total demand for a product over a short lifecycle of time, and the forecast is constantly revised as demand data is collected, which could be month-to-month.

Thus, a simple answer to the first of Dr. Jain’s questions is that there is no change in the relationship between strategic and operational planning. The former is still long-term and latter still short-term.

His second question was: “If so, what changes have occurred and why?” I believe that the major change since the pandemic is the need for a new formal operational planning process under uncertainty that I’ve termed quick response. It’s not the same as SOE, which is planning under risk.

In addition, the strategic planning and QR processes are strategically focused. Therefore, both processes have to be directed by someone from the executive suite because the risks are too high vis-a-vis those taken during the SOE and S&OP processes. Executives are needed to decide whether to make high risk existential decisions, and not just whether to buy green bananas.

- “Revisiting quick response,” Supply Chain Management Review, Jul/Aug 2022

- “Strategic planning under uncertainty: Long-term muddling-through,” Supply Chain Management Review, Jul/Aug 2021

- “Decision making under uncertainty: A primer,” Supply Chain Management Review, May/Jun 2022

- “Short lifecycle (SLC) forecasting for ‘muddling-through’ uncertainties,” Supply Chain Management Review, Nov 2021

SC

MR

Latest Supply Chain News

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- More News

Latest Podcast

Explore

Explore

Procurement & Sourcing News

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- There is still work to do to achieve supply chain stability

- Blooming success: The vital role of S&OE in nurturing global supply chains

- How one small part held up shipments of thousands of autos

- More Procurement & Sourcing

Latest Procurement & Sourcing Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks