Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

January-February 2017

Transformation is a topic that comes up in almost every conversation I have with supply chain managers these days. Executives from companies as diverse as J&J Vision Care, the division of Johnson & Johnson that manufactures contact lenses, and Thrive Markets, a startup selling health and wellness products to its members, have talked about how they have had to remake their supply chains to meet new customer demands. Transformation is also the theme of this issue of SCMR. Browse this issue archive.Need Help? Contact customer service 847-559-7581 More options

Unless you were an early adopter of one of those clunky analog true cellular phones that were only available with per-minute calling plans, you probably don’t have to look back beyond 15 years to remember your first mobile phone. The sales proposition was pretty universal across carriers: Sign a contract and get a free phone that would be subsidized by your monthly service payment. Then, every so often, you might be able to get an upgrade—but you probably had to switch providers to get the best “new customer” deals.

Those plans have almost all gone the way of the dodo. Service plans are now typically distinct from phone purchasing. Carriers often arrange financing options, but don’t actually subsidize the cost of the phone. Though trade-ins are still commonly referred to as upgrades, they are based on the remaining values of the devices that are turned in. So what changed, and why does it matter to you as a supply chain manager?

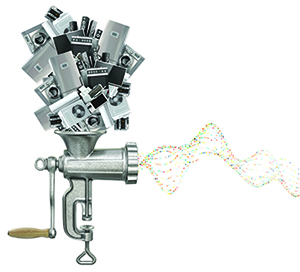

The seismic shift that affected practically the entire cell phone industry was the result of changes in the actual technology, its secondary market value and the supply chains that move the products. A slew of electronic products and everyday items not generally regarded as electronics, like appliances, are about to become technologically advanced, connected items as the Internet of Things explodes. As with the cell phone, manufacturers, distributors and retailers will not only manage the forward supply chain; they will also manage reverse logistics as some of those devices come back from the end user early in the sales cycle along with the repair, resale and ultimately the disposal of those products at the end of their useful life. The journey is akin to the cell phone’s evolution from analog bricks with pullout antennas to modern smartphones. That makes the cell phone industry the perfect barometer for anticipating game changing transformations in how manufacturers of all kinds will manage the lifecycles of the products they sell now that they are connected to the Internet and collecting personal data that must be managed.

This complete article is available to subscribers only.

Log in now for full access or start your PLUS+ subscription for instant access.

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

January-February 2017

Transformation is a topic that comes up in almost every conversation I have with supply chain managers these days. Executives from companies as diverse as J&J Vision Care, the division of Johnson & Johnson… Browse this issue archive. Access your online digital edition. Download a PDF file of the January-February 2017 issue.Unless you were an early adopter of one of those clunky analog true cellular phones that were only available with per-minute calling plans, you probably don't have to look back beyond 15 years to remember your first mobile phone. The sales proposition was pretty universal across carriers: Sign a contract and get a free phone that would be subsidized by your monthly service payment. Then, every so often, you might be able to get an upgrade—but you probably had to switch providers to get the best “new customer” deals.

Those plans have almost all gone the way of the dodo. Service plans are now typically distinct from phone purchasing. Carriers often arrange financing options, but don't actually subsidize the cost of the phone. Though trade-ins are still commonly referred to as upgrades, they are based on the remaining values of the devices that are turned in. So what changed, and why does it matter to you as a supply chain manager?

The seismic shift that affected practically the entire cell phone industry was the result of changes in the actual technology, its secondary market value and the supply chains that move the products. A slew of electronic products and everyday items not generally regarded as electronics, like appliances, are about to become technologically advanced, connected items as the Internet of Things explodes. As with the cell phone, manufacturers, distributors and retailers will not only manage the forward supply chain; they will also manage reverse logistics as some of those devices come back from the end user early in the sales cycle along with the repair, resale and ultimately the disposal of those products at the end of their useful life. The journey is akin to the cell phone's evolution from analog bricks with pullout antennas to modern smartphones. That makes the cell phone industry the perfect barometer for anticipating game changing transformations in how manufacturers of all kinds will manage the lifecycles of the products they sell now that they are connected to the Internet and collecting personal data that must be managed.

SC

MR

Latest Supply Chain News

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- Tips for CIOs to overcome technology talent acquisition troubles

- There is still work to do to achieve supply chain stability

- More News

Latest Podcast

Explore

Explore

Latest Supply Chain News

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- Tips for CIOs to overcome technology talent acquisition troubles

- There is still work to do to achieve supply chain stability

- Blooming success: The vital role of S&OE in nurturing global supply chains

- More latest news

Latest Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks