As a procurement professional, you may have been caught in one of these dilemmas:

Your CFO continually asks you to reduce inventory to control costs, yet you need that inventory to ensure on-time delivery to your customers.

A particular plant keeps too many parts on hand, yet the plant manager can't figure out a way to permanently reduce the number of parts.

- You're going into negotiations with a supplier who is charging a price that is higher than market rate. Is it possible to get that supplier to lower their rate?

With the appropriate metrics you can solve all three problems.

Not only do metrics measure something or the results of something, the right metrics enable supply management professionals to drive positive changes in their company that can be measured, creating alignment between competing objectives. The old saying “What gets measured gets done” is true: if you don't have metrics, you can't expect to make any change.

The right metrics executed strategically and with an integrated approach across the company also will demonstrate the real value of the supply management function to executive management as much more than the old tagline for procurement, the “cost police.”

Types of metrics

There's a multitude of supply chain metrics covering sourcing, inventory, manufacturing, warehousing, material handling, transportation, distribution and customer service. If you're not careful you could easily slip into “analysis paralysis” of endlessly trying to figure out which measures to select, or trying to measure everything.

This quote, rumored to have hung in Albert Einstein's Princeton University office, is a good warning to heed: “Not everything that counts can be counted, and not everything that can be counted counts.”

First you'll want to determine your business priorities. Whether you're trying to measure service levels from your suppliers or the consistency of your plants' operations, focus on the metrics that measure what is most vital to your business and can be reported and understood by your stakeholders. If possible, link your metrics specifically to your company's strategic priorities and objectives.

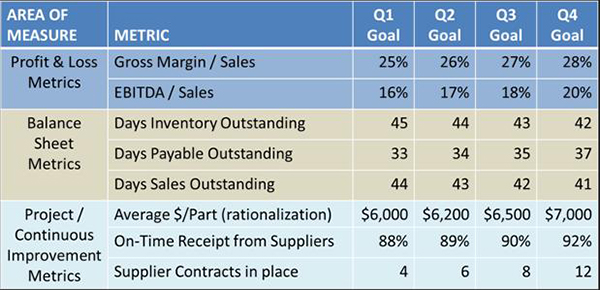

I recommend using a metric scorecard that is holistic and includes both the P&L statement and the balance sheet. It should also include one or two incremental projects that are truly “game changers” and will result in either solving a discrete problem or engaging in continuous improvement, or both.

Everyone in your organization should use the same scorecard – at least the same elements if not the same targets—otherwise there is neither consistency nor agreement on performance levels, and it will be difficult to impossible to leverage any good ideas.

Metrics drive improvement and change

People need to know what the goals are in order to change and improve a process or an activity. Without a metrics scorecard to use as a roadmap, you're just hoping that things will get better.

One of our clients is a US-headquartered manufacturer of components for a variety of industries and the military. After a series of acquisitions that spanned more than 10 years, it now operates 26 manufacturing plants in 11 countries. As a result, there are 26 different ways to do the same thing, including buying the same common materials such as metal and using hundreds of suppliers for a high volume category in the US alone.

The company recognized the huge opportunity it had to rationalize its operations, and asked ISM Services to develop a single, consistent scorecard for all its plants to reduce the number of machining suppliers. The scorecard will be piloted first in a few plants and ultimately rolled out to all, offering significant operational and cost benefits in the long term. It will give senior management a cohesive way to look at the business and will align with global goals concerning earnings per share and service level improvements throughout the enterprise.

As mentioned above, I've seen scorecards work best when they incorporate P&L, balance sheet and project objectives. Following is an example of such a scorecard at a business unit or plant level:

Metrics create alignment

Whether it's between a company and its key suppliers or between internal departments within one company, alignment of goals and objectives is critical to getting work done efficiently and effectively. Again, using a metric scorecard is key.

A client in the medical technologies and services industry we have worked with used metrics to analyze the cost of one component in a piece of medical equipment. It determined the key supplier was charging a higher price than the competition for that particular part. During contract negotiations, the supplier refused to collaborate with the company to find a way to reduce the cost.

As a result of the supplier's intractability the medical technologies company created new specifications, writing that supplier out of the competition. Losing that part of the business was a rude awakening for the supplier to the benefits of collaboration and cooperation.

Another client that manufactures processed foods uses an internal scorecard to align its team's efforts as they manage a supply chain that serves the 10 customers that generate more than 80 percent of the client's revenue. The customer-centric scorecard is shared among a cross-functional team so everyone knows exactly the goals and objectives. This scorecard had shared elements between customer service, operations, logistics, back office functions and sales

Metrics elevate the supply management function

As the supply management industry continues to educate and inform executive management about the value it brings to the corporate bottom line, the strategic use of metrics reinforces the case.

Through performance measures like order-fill rates, on-time delivery and services levels, you can demonstrate how well you are providing for your customers. Other measures will demonstrate how well you're managing your business, such as material cost and manufacturing cost.

At the highest level, your performance measures developed through your metrics plan will show how supply management functions are increasing shareholder value by making the business more competitive and more profitable. You can also better measure your successes, and may be able to use the results to have a more important say in your organization. And increasing the visibility of supply chain best practices is a goal we should all have.

SC

MR

Latest Supply Chain News

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- More News

Latest Resources

Explore

Explore

Latest Supply Chain News

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- More latest news

Latest Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks