If you have children of a certain age, you might remember the movie Matilda, which was based on a book of the same name by Roald Dahl. One of my favorite lines involves the cruel headmistress of a rundown elementary school who can see no useful purpose for young children. “My idea of a perfect school,” she says, “is one that has no children in it at all.”

One of the promises of what are known as disruptive technologies is lights out manufacturing. That is a manufacturing process – or entire manufacturing facility – that could theoretically operate in the dark because, like Miss Trunchbull's school, no people are required in that operation.

Whether you find that idea exciting or frightening, lights out manufacturing processes is a goal for many manufacturers, including HIROTEC AMERICA, a Tier 1 OEM of weld assembly equipment to leading automotive manufacturers. “Our goal, and it's a stretch goal, is to get to zero operators for spare parts,” says Gary Krus, vice president of business development (R&D). Indeed, Krus says Hirotec has been talking about the concept of lights out manufacturing during most of his 24 years with the company. While the company has been removing people from its processes where possible for years, using, for instance, robotic welding and other flexible manufacturing tools, the hurdle has always been that the available technology has not yet lived up to the goal. For instance, even if a process at an assembly station could be automated, it still required people to sequence and deliver parts from one station to the next.

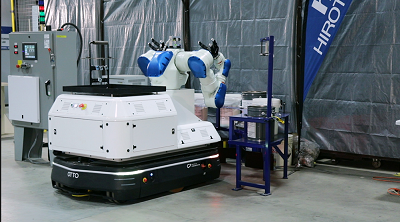

Those barriers are beginning to come down, and mobile robotics is one of the reasons why. In one of its U.S. plants, HIROTEC AMERICA has recently gone live with a mobile - piece picking robot to completely automate the black oxide process for spare parts production. The robotic solution involves a mobile, self-driving robot from OTTO and an integrated dual-arm piece-picking robot from Yaskawa Motoman.

Currently parts are still delivered to the work station. Once there, the mobile robot moves into place, the system downloads instructions and then the robotic arms perform the process of dipping parts, moving from bucket to bucket in a timed sequence that coats the parts to provide a corrosion resistant surface. That's step one. The ultimate goal is for the robots to pick up the parts from the machine shop and then deliver them to the next step in the process. Lights out!

You can read more about this solution here and watch a video of the robot in action here.

It is admittedly a first-step in a low-volume process and there is more to be done. “I think we're three to five years away from processes like this really catching on, and we're probably just 75 percent down the road to automating the whole process,” Krus says. “And, realistically, I think we're probably 20 years away from a robot that can do everything that a human does. Getting there is going to require more vision technologies, more sensing and more computing power.”

At the same time, based on his experience with the black oxide process, Krus is looking for other steps in the overall manufacturing process that are ripe for this type of automation. “I'm not looking to get rid of people – I'll still need them for maintenance,” Krus says. “What I want is to increase throughput with more flexibility, more timely delivery of parts to the lines and a safer work environment.”

SC

MR

Latest Supply Chain News

- Technology’s role in mending supply chain fragility after recent disruptions

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- More News

Latest Resources

Explore

Explore

Latest Supply Chain News

- Technology’s role in mending supply chain fragility after recent disruptions

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- How S&OP provides the answer to in-demand products

- More latest news

Latest Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks