A majority of executives at large global companies expect the Industrial Internet of Things (IIoT) to significantly impact business performance and competitiveness over the next three years, according to a new study just released by the Business Performance Innovation (BPI) Network. However, many companies are lagging in IoT readiness, setting the stage for competitive advances and dislocation among IoT leaders and laggards.

“Executives point to better supply chain intelligence as one of the key areas they are looking towards when it comes to IIoT technologies and their ability to achieve measurable performance improvement,” says Sally Lopez, Content Director with the BPI Network.

In an interview with SCMR she adds that Executives also agree that currently supply chain logistics is in the top three areas of current IIoT investment. They believe greater insights into the supply chain will be a key benefit for customers.

The study also suggests that large-scale integrators and other channel partners will be among the biggest IIoT beneficiaries over the next several years. They will likely play a significant role in planning and implementation at many companies due to major internal gaps in the technical skills and management know-how needed to deploy and integrate IoT into operations and new products.

The new report, “The Impact of Connectedness on Competiveness,” was developed by the BPI Network in partnership with the CMO Council, Penton's IoT Institute, and The Nerdery, a leading digital strategy, software engineering and design firm. The study was based on a global survey of some 350 executives around the world and interviews with innovation leaders at large global enterprises, including companies such as Airbus, Balfour Beatty, Embraer, Philips Lighting, GE, Whirlpool, LafargeHolcim, TVH, Hitachi, and others.

“Executives are telling us that IIoT technologies are about to play a significant role in business and industrial performance, delivering significant improvements in operational efficiency and uptime, as well as growth from new business models, products, services and customer experiences,” said Dave Murray, head of thought leadership for the BPI Network. “Nevertheless, less than 2 percent of large companies say they have a clear vision for how to move forward or have large-scale implementations underway. That dichotomy suggests we are experiencing the lull before the storm of IoT transformation. This is an opportunity for real competitive differentiation and advancement.”

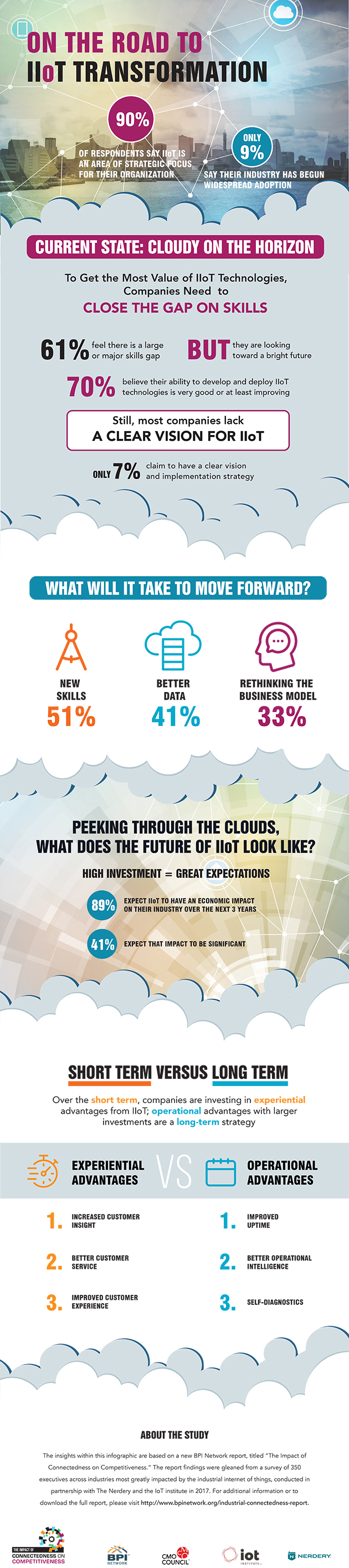

Among key findings of the IIoT survey:

- 52 percent of executives at large enterprises, and 41 percent of executives at all companies, expect IIoT to have a significant or major impact on their industry within three years. Some 55 percent of all executives say IIoT is gaining adoption within their industries, including both pilots and larger-scale adoption.

- However, just 1.5 percent of executives at large companies say they have a “clear vision with implementation well underway,” while another 57 percent are either beginning implementation, have pilots underway or are committed and in the planning stages.

- New products and services lead as the area most companies say they will focus their IoT investments (35 percent), followed by customer touch points (29 percent), and manufacturing (23 percent).

- More cost-efficient operations (47 percent), product and service differentiation (36 percent) and improved customer engagement and satisfaction (34 percent) are seen as the top benefits of IIoT.

- Security and data privacy are seen as top concerns by executives, followed by the cost and complexity of Industrial IoT adoption and the need for new management and workforce skills and training.

“The tidal wave that is connectedness and IIoT is building rapidly and it is unavoidable,” said Chris Locher, Vice President of Software Development at The Nerdery. “Companies see massive opportunities to increase efficiency, gather data in new ways and pivot into new business models. The challenge of the IIoT revolution is that it is accompanied by a great deal of white noise and confusion. How will companies capture those opportunities? How do companies avoid the risk of a failing at an IIoT initiative? How do you find employees with the skill to do it? The sheer scale and implications of IIoT can lead to information overload, create analysis paralysis, and confusion for business leaders. The key to moving confidently into this new space is starting with small, focused efforts or bringing experts to start to build the required skills, behaviors, and business models.”

IoT Readiness Lacking

Making the transformation to IIoT-enabled business will clearly require new skills and management thinking. Chief among those requirements, according to executives, are new technical skills (51 percent), better data integration and analytics capabilities (41 percent), and rethinking of business model (33 percent). Most executives, however, say their companies have significant gaps in these areas.

Some 31 percent of executives say their organizations face a “major skill gap” in their IoT readiness, while another 31 percent say the talent gap is “large, but improving somewhat.” Twenty percent say their IoT skills are quickly improving, while another 7 percent believe they have most of the skills in place.

Similarly, just 12 percent give their company an “excellent” rating in their capacity to develop and deploy applications that utilize real-time insights and systems monitoring. However, another 35 percent rate that capacity as “good.” One third rate their corporation's ability in this area as “moderate and improving.”

“Global businesses clearly are working to put the needed skills in place to address the opportunity of connected, intelligent products and machines, but those talents are in short supply. We can expect for the time being that system integrators, consulting and software engineering firms with the right skills in connectivity, sensor technology, data analytics and complex integration will benefit from the race to keep pace with IoT enablement,” said Murray.

Creating IoT Value

Interviews with executives at large businesses that are deploying or planning for Industrial IoT applications underscore the wide range of benefits and scenarios represented by these technologies.

Embraer, the world's largest regional jet maker, for example, says new jets that integrate sensors to identify and predict maintenance needs now have a remarkable “99.5 percent dispatching rate,” in which less than 0.5 percent of planned take-offs are affected by unexpected maintenance issues, according to Alexandre Baule, VP of Information Systems at Embraer. Embraer and its partners are also working toward an IoT-enabled customized experience for passengers, in which each person's favorite movies, music, and even temperature settings are available before they take their seats.

Airbus, one of the world's two largest aircraft manufacturers, is also integrating sensor technology to improve the predictability and safety of its aircraft, but also envisions widespread use of IoT technology in its “Factory of the Future”—a platform approach that will include cyber-physical systems, 3-D printed prototypes, open robot interfaces and advanced data analytics to increase the quality and productivity of its manufacturing processes. Factory workers use smart glasses and advanced image processing to track problems, tools and solutions in real-time, while exoskeletons are developed to reduce risk and enhance human capabilities.

Download the full report here.

SC

MR

More IoT

- Inflation continues to have a wide-ranging impact on supply chains

- Tech investments bring revenue increases, survey finds

- Tips for CIOs to overcome technology talent acquisition troubles

- Maximizing Return on Innovation Investment: 6 Ingredients for Success

- Global IoT spend by logistics market to top $114 billion by 2032

- Industrial IoT market to reach $1.3 trillion by 2032

- More IoT

Latest Resources

Explore

Explore

Software & Technology News

- Inflation continues to have a wide-ranging impact on supply chains

- Technology’s role in mending supply chain fragility after recent disruptions

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- More Software & Technology

Latest Software & Technology Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks