We find that most supply chain professionals fall into one of two camps. Either they need to completely transform their supply chain, or they have a supply chain strategy that is not generating the results they expect and need. Many of them realize that the lack of a good supply chain strategy is a major problem causing their supply chain to flounder without having a real direction.

We often see companies who don’t have a supply chain strategy chasing the latest hot trend or flavor of the month. Like a ship without a rudder, any wind is favorable. People in these companies complain that there are too many initiatives. As one executive said, “All we do is launch and then leave initiatives. We rarely focus on the critical few and complete them. There are just too many initiatives. We have no strategy.”

We have worked with well over 100 firms through the University of Tennessee, Knoxville’s Supply Chain Forum, as well as through the supply chain audits we do for companies. We continue to be surprised at the paucity of real strategy work. In a range of companies representing manufacturers and retailers of all sizes across many industries, we saw up-to-date, multi-year supply chain strategies in only about one in five companies. Recently, we surveyed 40 firms more formally, and 62 percent said they have a supply chain strategy. But, upon further probing, only 30 percent of those respondents confirmed that their strategy was a documented, multi-year strategy. Thus, only 30 percent of the 62 percent or 18 percent of the companies could produce an up-to-date supply chain strategy document with a roadmap that goes out at least three years.

What’s Different about a Supply Chain Strategy?

Unlike other areas of the firm, the supply chain process is a horizontal end-to-end process guiding the seamless flow of product across the extended enterprise. Products flow through the firm from suppliers to customers. But this flow must in effect pass smoothly through vertical functional barriers. In addition, the requirements of the customer must guide the flow, and those requirements must flow smoothly back through the functional barriers. Because of this highly complex, cross-functional, cross-company challenge, a supply chain strategy represents a different set of challenges in its scope, its development, and especially in getting buy-in to do it.

The State of Supply Chain Strategy Development Today?

Some additional information from our survey of 40 companies is outlined below:

What Encompasses a Supply Chain Strategy?

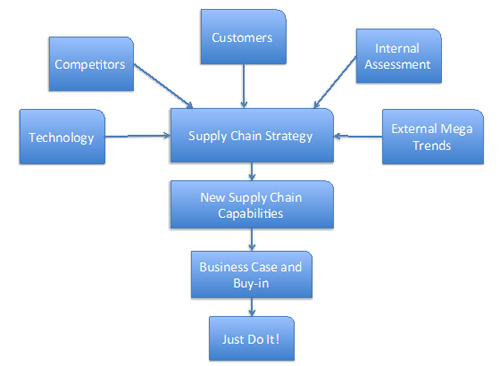

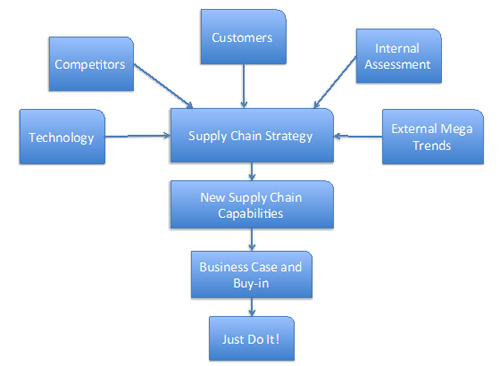

As depicted in the figure below, an effective supply chain strategy must start with the needs of your customers. It must comprehend the threats generated by foreign and domestic competition. It must recognize the most likely socio-economic and demographic scenarios that may occur. It must honestly evaluate the strengths, weaknesses, opportunities, and threats (SWOTs) faced by the firm. It must account for the evolving technology that is, and will be, available. It must satisfy the financial goals of the company. And finally, it must do something! Namely, it must generate a set of actions that create the capabilities the firm will need in the future.

Figure 1: Elements of a Supply Chain Strategy

As with any strategy, a supply chain strategy must analyze all of the inputs above, determine the critical issues to address, define a strategy to deal with these critical issues, and then identify a set of action plans to develop new and enhanced capabilities.

How Good is Your Supply Chain Strategy? A Self-Test

This self-test is included to help you assess the sufficiency of your supply chain strategy.

Table1-2: Supply Chain Strategy Evaluation Scoring: If you scored 85- 110 points, congratulations. You have the foundation of an excellent strategic planning process. If you scored 70-85 points, you have the foundation of a good strategy process. If you scored below 70 points, you have much work to do to develop and implement a supply chain strategy process.SC

We often see companies who don’t have a supply chain strategy chasing the latest hot trend or flavor of the month. Like a ship without a rudder, any wind is favorable. People in these companies complain that there are too many initiatives. As one executive said, “All we do is launch and then leave initiatives. We rarely focus on the critical few and complete them. There are just too many initiatives. We have no strategy.”

We have worked with well over 100 firms through the University of Tennessee, Knoxville’s Supply Chain Forum, as well as through the supply chain audits we do for companies. We continue to be surprised at the paucity of real strategy work. In a range of companies representing manufacturers and retailers of all sizes across many industries, we saw up-to-date, multi-year supply chain strategies in only about one in five companies. Recently, we surveyed 40 firms more formally, and 62 percent said they have a supply chain strategy. But, upon further probing, only 30 percent of those respondents confirmed that their strategy was a documented, multi-year strategy. Thus, only 30 percent of the 62 percent or 18 percent of the companies could produce an up-to-date supply chain strategy document with a roadmap that goes out at least three years.

What’s Different about a Supply Chain Strategy?

Unlike other areas of the firm, the supply chain process is a horizontal end-to-end process guiding the seamless flow of product across the extended enterprise. Products flow through the firm from suppliers to customers. But this flow must in effect pass smoothly through vertical functional barriers. In addition, the requirements of the customer must guide the flow, and those requirements must flow smoothly back through the functional barriers. Because of this highly complex, cross-functional, cross-company challenge, a supply chain strategy represents a different set of challenges in its scope, its development, and especially in getting buy-in to do it.

The State of Supply Chain Strategy Development Today?

Some additional information from our survey of 40 companies is outlined below:

- Of those companies who do not have a supply chain strategy, the main reason seems to be lack of resources to develop one. But virtually all firms indicate that they hope to develop a strategy in the future.

- Listed below are the percentage of existing strategies that consider the following topics:

- Best practice in supply chain analysis—83 percent

- Interface with corporate strategy—80 percent

- Technology assessment—67 percent

- Competitive analysis—55 percent

- Customer-needs assessment—50 percent

- Internal SWOT analysis—50 percent

- Social/demographic trends—5 percent

- Seventy-eight percent of the strategies go three to five years into the future. But, 22 percent only cover the short-term, one to two-year period, putting those more in the operating plan category as opposed to a strategic plan.

- Resources used to develop the strategy were:

- Consultants—55 percent

- Corporate staff—40 percent

- Supply chain staff—38 percent

- Supply chain line—38 percent

- Customers—8 percent

- Logistics providers—8 percent

- In only 45 percent of the cases were consultants considered to have added a lot of value. Most said they could have developed the strategy without the help of consultants.

- Areas addressed by the strategy were:

- Transportation—90 percent

- Inventory management—76 percent

- Fill rates/product availability—75 percent

- Warehousing—75 percent

- IT decision support systems—66 percent

- Suppliers—56 percent

- Procurement—52 percent

- Manufacturing—55 percent

- Customers—38 percent

- Environmental—42 percent

- And the most surprising and disappointing finding of all: Cross-functional buy-in to the supply chain strategy was good or excellent in only 24 percent of the cases. Only 8 percent reported excellent buy-in! Buy-in was average to poor in the remaining 76 percent of cases, indicating that cross-functional acceptance of a supply chain strategy is a huge challenge, requiring a major change management effort.

What Encompasses a Supply Chain Strategy?

As depicted in the figure below, an effective supply chain strategy must start with the needs of your customers. It must comprehend the threats generated by foreign and domestic competition. It must recognize the most likely socio-economic and demographic scenarios that may occur. It must honestly evaluate the strengths, weaknesses, opportunities, and threats (SWOTs) faced by the firm. It must account for the evolving technology that is, and will be, available. It must satisfy the financial goals of the company. And finally, it must do something! Namely, it must generate a set of actions that create the capabilities the firm will need in the future.

Figure 1: Elements of a Supply Chain Strategy

As with any strategy, a supply chain strategy must analyze all of the inputs above, determine the critical issues to address, define a strategy to deal with these critical issues, and then identify a set of action plans to develop new and enhanced capabilities.

How Good is Your Supply Chain Strategy? A Self-Test

This self-test is included to help you assess the sufficiency of your supply chain strategy.

| Question | Rating from 1 to 10 |

| 1. Do you know what your customers will need in the future, and have you translated the future needs of your customers into supply chain requirements? | |

| 2. Have you completed a SWOT assessment for your supply chain, comparing your capabilities versus best-in-class? | |

| 3. Have you assessed the external environment, including the supply chain mega trends and how they may impact you? (Assuming you have identified the supply chain megatrends?) | |

| 4. Have you analyzed the supply chains of your major competitors? | |

| 5. Have you evaluated the future technology environment for your supply chain? | |

| 6. Have you prioritized the risks associated with your supply chain, and do you have a risk mitigation plan in place to deal with the highest priority risks? | |

| 7. Have you assessed the global requirements of your supply chain? Have you identified the supply chain issues in each country you will do business in? | |

| 8. Do you have in place a three-year or longer roadmap of supply chain initiatives driven by a strategic plan? | |

| 9. Are the initiatives prioritized and project-managed in a disciplined way such that they are delivered on time, on budget, and on benefit? | |

| 10. Do you completely update the strategy at least every three years? | |

| 11. Are you delivering world-class results in cost reduction, working capital management, and product availability that are best in class? |

Table1-2: Supply Chain Strategy Evaluation Scoring: If you scored 85- 110 points, congratulations. You have the foundation of an excellent strategic planning process. If you scored 70-85 points, you have the foundation of a good strategy process. If you scored below 70 points, you have much work to do to develop and implement a supply chain strategy process.

SC

MR

Subscribe to our weekly e-mail update

Don’t miss out on the best in supply chain. Latest Supply Chain News

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- Tips for CIOs to overcome technology talent acquisition troubles

- There is still work to do to achieve supply chain stability

- Blooming success: The vital role of S&OE in nurturing global supply chains

- More News

Latest Resources

The Ultimate WMS Checklist: Find the Perfect Fit

Avoid costly mistakes by choosing the perfect WMS for your company with our comprehensive buyer's guide. Get your checklist now!

Explore

Explore

Topics

Latest Supply Chain News

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- Tips for CIOs to overcome technology talent acquisition troubles

- There is still work to do to achieve supply chain stability

- Blooming success: The vital role of S&OE in nurturing global supply chains

- Supply chain salaries, job satisfaction on the rise

- More latest news

Latest Resources

Frictionless Videocast: The Importance of Water at the U.S./Mexico Border

Listen as Dr. Maria Elena Giner, Commissioner of the US International Boundary and Water Commission, and Rosemary Coates, Executive Director of…

Subscribe

Supply Chain Management Review delivers the best industry content.

Subscribe today and get full access to all of Supply Chain Management Review’s exclusive content, email newsletters, premium resources and in-depth, comprehensive feature articles written by the industry's top experts on the subjects that matter most to supply chain professionals.

Editors’ Picks

Port of Baltimore May Not Reopen Until Summer

The Port of Baltimore may remain closed until at least May, and possibly into…

A New Priority Greets Procurement Professionals in 2024

Cost reduction supplants supply continuity as the top issue facing…

Supply Chains Facing New Pressures as Companies Seek Cost Savings

A Boston Consulting Group survey of global executives found a majority are…

Digital Approaches, End-to-End Thinking Help Supply Chains Evolve

Supply chain disruptions come in many forms, but digital approaches and…

© Copyright 2024 Supply Chain Management Review, a division of Peerless Media. All Rights Reserved.

×

![]()