Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

November 2021

This is the last regular issue of Supply Chain Management Review for 2021. Normally this time of year, I look forward to what’s in front of us. That’s turned out to be a fool’s errand over the last year and a half. So, instead, I looked back to see what I wrote this time last year. My column was titled “COVID hasn’t stopped supply chain progress.” Browse this issue archive.Need Help? Contact customer service 847-559-7581 More options

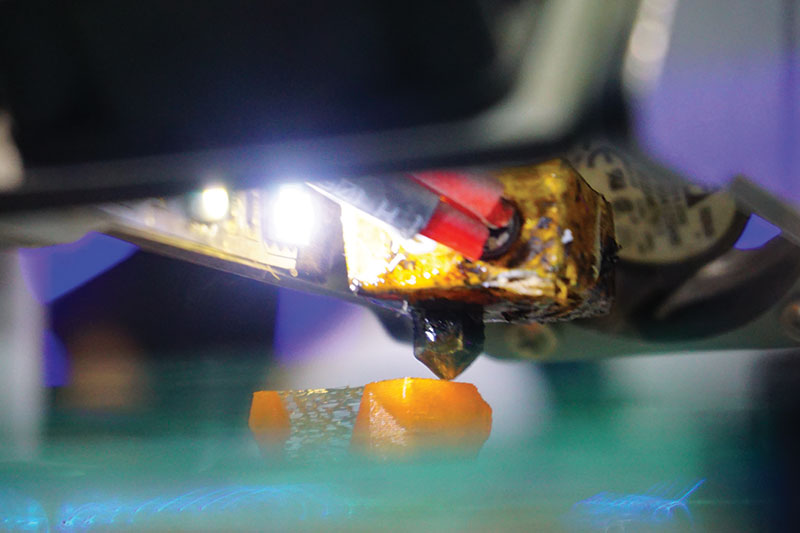

Despite more than 25 years of success, 3D printing/additive manufacturing (AM) finds itself in a peculiar spot.

Thanks to the efforts of countless researchers and engineers, the core AM technologies have matured into competent and dependable manufacturing processes. And it’s happened in industries as diverse as automotive, aerospace and medical implants, to name three.

In terms of engineering performance, there is an AM technology for nearly every need.

For many companies, AM is the go-to technology for producing functional prototypes and manufacturing aids. For these limited-quantity items, AM is a natural fit, far more economical than CNC machining or injection molding. At-scale production, however, is still a ways off for all but the most advanced and dedicated manufacturers.

That brings us to AM’s peculiar spot. On the one hand, the technology has already answered the question: “can I print it?” with a resounding “yes.” However, we aren’t quite at the point where the same enthusiastic answer works for the question: “Should I print it?”

A steppingstone to at-scale production may be spare parts. The on-demand nature of AM seems to be especially well suited to low-volume or unpredictable spare part production requests. Typically, 3D printing is well positioned to eliminate exorbitant retooling costs and seamlessly embraces the next generation of digital warehousing.

This complete article is available to subscribers only.

Log in now for full access or start your PLUS+ subscription for instant access.

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

November 2021

This is the last regular issue of Supply Chain Management Review for 2021. Normally this time of year, I look forward to what’s in front of us. That’s turned out to be a fool’s errand over the last year and a… Browse this issue archive. Access your online digital edition. Download a PDF file of the November 2021 issue.Despite more than 25 years of success, 3D printing/additive manufacturing (AM) finds itself in a peculiar spot.

Thanks to the efforts of countless researchers and engineers, the core AM technologies have matured into competent and dependable manufacturing processes. And it’s happened in industries as diverse as automotive, aerospace and medical implants, to name three.

In terms of engineering performance, there is an AM technology for nearly every need.

For many companies, AM is the go-to technology for producing functional prototypes and manufacturing aids. For these limited-quantity items, AM is a natural fit, far more economical than CNC machining or injection molding. At-scale production, however, is still a ways off for all but the most advanced and dedicated manufacturers.

That brings us to AM’s peculiar spot. On the one hand, the technology has already answered the question: “can I print it?” with a resounding “yes.” However, we aren’t quite at the point where the same enthusiastic answer works for the question: “Should I print it?”

A steppingstone to at-scale production may be spare parts. The on-demand nature of AM seems to be especially well suited to low-volume or unpredictable spare part production requests. Typically, 3D printing is well positioned to eliminate exorbitant retooling costs and seamlessly embraces the next generation of digital warehousing.

SC

MR

Latest Supply Chain News

- April manufacturing output slides after growing in March

- Q1 sees a solid finish with positive U.S.-bound import growth, notes S&P Global Market Intelligence

- World Trade Centers offers a helping hand to create resilient, interconnected supply chains

- 6 Questions With … Sandeep Bhide

- MIT CTL offering humanitarian logistics course

- More News

Latest Podcast

Explore

Explore

Software & Technology News

- Technology’s role in mending supply chain fragility after recent disruptions

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- Tips for CIOs to overcome technology talent acquisition troubles

- More Software & Technology

Latest Software & Technology Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks