Globalization, increased competition, fluctuating availability of raw materials and pricing conditions have increased the need for better management of the suppliers who provide goods and services to the organization. According to the U.S. Census Bureau, the cost of purchased materials is approximately 54% of the value of shipments for manufacturers. Also, the cost of services that organizations purchase is continuing to increase as firms try to focus on what they do best.

More emphasis is being placed on spend management and on those that are responsible for locating and managing the suppliers that provide the materials and services needed to meet customer expectations. Sourcing and procurement are generally responsible for this task. A focus on spend management is not new to the purchasing area. But the increasing magnitude of requested reductions is driving purchasing departments to think creatively about ways to more strategically manage the supply base and continue to drive unnecessary costs from everyday purchases.

The task of sourcing and procurement professionals is to find an effective means to balance the demands of both internal and external customers with economic considerations while taking into account the potential for supply disruption and technological change.

Strategic purchasing involves finding ways to use supplier capabilities to drive sales, leverage the purchasing spend to achieve and/or maintain competitive advantage, and use the supply market to strengthen the company’s strategic position.

Historically, purchasing has been overlooked as a strategic contributor and instead viewed as more of a tactical function with a largely internal focus. The tendency of even the most seasoned buyers has been to react to problems rather than proactively incorporate the strategic focus needed to support the current operating environment. The primary focus of procurement is to support the firm’s operational requirements by ensuring uninterrupted flow of the appropriate quality materials, products, and services. However, purchasers must do so in the most efficient and effective manner, in light of limited resources. The key for sourcing managers is to minimize risk to the organization.

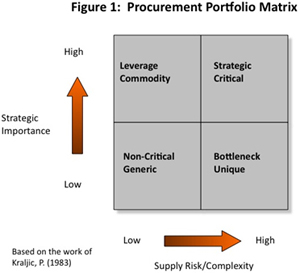

To minimize vulnerabilities in supply and make the most of the organization’s buying power, purchasers should assess and segment purchased materials, services, and components in terms of importance to the organization and difficulty in accessing the materials. This segmentation process allows purchasers to take a more strategic perspective on the management of the supplies and the supply base while applying more appropriate cost management tools and negotiation strategies.

Using the segmentation system developed by Kraljic (1983) as a foundation, four major categories emerge (see Figure 1). Noncritical (low importance, low supply risk), leverage (high importance, low supply risk), strategic (high importance, high supply risk), and bottleneck (low importance, high supply risk). Each of the categories requires a distinctive and strategic purchasing approach. Each of these classifications will be described in the paragraphs below.

Using the segmentation system developed by Kraljic (1983) as a foundation, four major categories emerge (see Figure 1). Noncritical (low importance, low supply risk), leverage (high importance, low supply risk), strategic (high importance, high supply risk), and bottleneck (low importance, high supply risk). Each of the categories requires a distinctive and strategic purchasing approach. Each of these classifications will be described in the paragraphs below.

In the case of non-critical, or generic purchases, the focus is on finding the lowest possible purchase price from a field of many suppliers. For these types of items, there are low switching costs allowing for easy “supplier hopping”. Typical procurement approaches to these types of purchases include the use of purchasing cards (p-cards) and short-term contracts. Relationships with the suppliers of these types of products are often arms-length and transactional. Office supplies and paper purchases typically fall into this category. Buyers use competitive bidding, price indices, price lists and catalogs to facilitate the buying process. The suppliers of these types of materials and services understand that low price and ease of purchase are key to retaining buyers. Staples, for example, introduced the “Easy Button”. Buyers that are in the market for office supplies can download software directly to their computer, shop from on-line catalogs, and use their p-cards to streamline the purchases of these generic items.

Many suppliers are capable of providing the products and services that fall into the leverage category; these are the more “commodity-type” items. These types of products and services have a great importance to the organization in terms of volume purchased, percentage of total purchase cost, or impact on product quality or business growth. The purchasing decision for these items is generally based on consolidation, leveraging volumes is key to success. Some approaches used to leverage volume include supply base reduction and reverse auctions. The idea is to combine the requirements of different operating units and capitalize on supplier fixed cost allocation and improved productivity. The following example makes the point.

A technology company had multiple business units all with individuals responsible for the purchase of customer contact center services. Through informal discussions about the performance of the suppliers of these services, the heads of the business units discovered that some were using the same suppliers, but being charged different rates and there were multiple suppliers providing almost identical services across the organization. The purchasing area was called in to help better manage the purchase of these services.

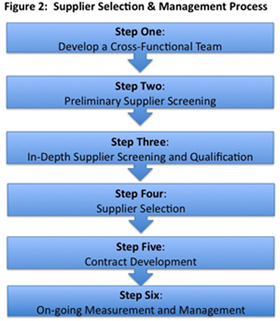

They followed a typical sourcing process (see Figure 2) and put these services out for bid to both existing and new suppliers. The final pool of suppliers included fewer suppliers, volumes were leveraged, the price that was being paid ultimately fell, and the relationship with the suppliers improved. The company instituted a single point of contact for the suppliers and an end-to-end procure to pay management process (Ellram and Tate, 2004).

They followed a typical sourcing process (see Figure 2) and put these services out for bid to both existing and new suppliers. The final pool of suppliers included fewer suppliers, volumes were leveraged, the price that was being paid ultimately fell, and the relationship with the suppliers improved. The company instituted a single point of contact for the suppliers and an end-to-end procure to pay management process (Ellram and Tate, 2004).

The strategic items have more complexity and risk involved in the purchase often because of limited availability or fewer suppliers with the technical capabilities to provide the goods or services. These are the items that are the most critical for the organization to obtain to ensure success and meet the demand for products. There is much more collaboration and integration between the buying and supplying firm with a focus on continuous improvement. Buying firms often enter into long term, cost-based contracts with the suppliers of these items and may in fact engage the suppliers early in the process of new product development. Buyers look to these suppliers for innovation and cost reduction ideas. Ford and Mobil for example entered into a broad based strategic alliance to speed the development and integration of break-through fuel and vehicle technologies (Dieselnet, 1998). The intent of these strategic alliances is to help strengthen collaboration, and develop a sustainable business model.

Bottleneck items, or items that are more project oriented or unique, have a high level of supply market complexity. These types of purchases often consume a disproportionate amount of time, relative to the item’s value. The focus for purchasing is to simplify the procurement of these items, or if possible get it out of this quadrant and into the leverage or strategic quadrants. Companies buying products or services that fall in the category could participate in buying consortiums to better leverage the spend and minimize the associated risk. For example, a utility company was paying a significant amount of money to audit their suppliers. A number of their competitors were using the same suppliers and spending the same money for the audits.

These companies agreed to hire a third party to perform the audits, thus consolidating the spend and simplifying the purchase. Another company was procuring project-based environmental services. Each project required the buyer to closely manage the supplier to ensure that each step in the process was completed in a timely and accurate fashion and that payments were made as promised. There were many of these projects occurring simultaneously with different suppliers. One supplier became an “expert” in this area allowing the buying firm to assign the supplier more projects, thus increasing the level of importance and moving it to the strategic category.

Successful managers today require a broad view of the procurement and sourcing areas and the strategic role that this function can play in an integrated supply chain. Organizations need to take a long-term perspective, avoiding the low price sourcing temptation without considering the total cost and the total value provided by the function and its relationship to the supply base. Purchasing needs to strategically manage its supplies and its supply base. The first step in doing this is to understand what is being purchased, the importance of the purchase to the organization, and the complexity of the supply market. The goal is to ensure that the supplies that are purchased add value to the customer’s that ultimately buy our goods and services.

References:

Dieselnet (1998). “What’s New? Ford and Mobil Form Strategic Alliance,” Accessed from http://www.dieselnet.com/news/1998/03ford.php on September 20, 2010.

Ellram, L.M. and W.L. Tate (2004). “Managing and Controlling the Services Supply Chain at Intuit,” CAPS Research, Practix: Good Practices in Purchasing & Supply Management, Vol. 7, August.

Kraljic, Peter (1983). “Purchasing Must Become Supply Management,” Harvard Business Review, September-October, pp. 109-117.

In examining the basics, our experts from the University of Tennessee will explain how mastery in the following areas leads to success on the bigger supply chain stage:

- MANAGING THE BASIC SUPPLY CHAIN FUNCTIONS (Part 1)

- TRANSPORTATION (Part 2)

- WAREHOUSING (Part 3)

- SOURCING and PROCUREMENT (Part 4)

- RETURNS MANAGEMENT (Part 5)

- POST-SALES SERVICE (Part 6)

- PARTNERSHIPS and COLLABORATION (Part 7)

Make sure you are on our eNewsetter list so we can notify you when the next series is online.

For more articles on Sourcing and Procurement, check-out our Sourcing and Procurement Critical Topics page

SC

MR

Latest Supply Chain News

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- Tips for CIOs to overcome technology talent acquisition troubles

- There is still work to do to achieve supply chain stability

- More News

Latest Podcast

Explore

Explore

Latest Supply Chain News

- How S&OP provides the answer to in-demand products

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- Tips for CIOs to overcome technology talent acquisition troubles

- There is still work to do to achieve supply chain stability

- Blooming success: The vital role of S&OE in nurturing global supply chains

- More latest news

Latest Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks