Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

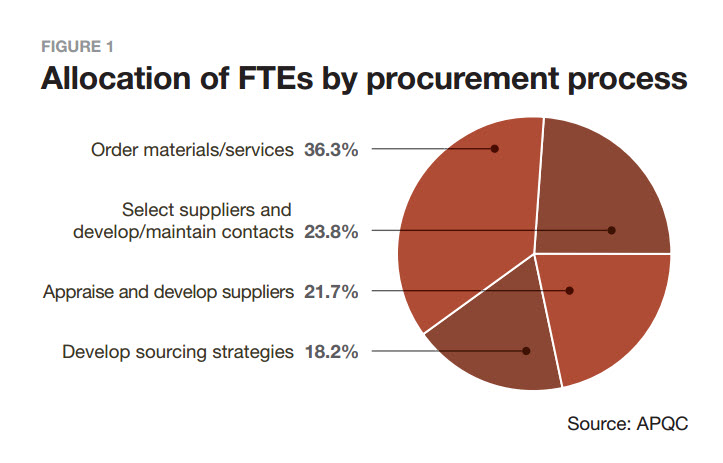

When organizations think of the areas in their supply chains on which to focus to deliver cost reduction, they often select the procurement function. This is understandable because it is easy for an organization to incur extra costs in procurement due to inefficiencies in ordering and purchasing activities. In fact, when looking at its Open Standards Benchmarking data in procurement, APQC has found that organizations have the largest group of their procurement full-time equivalent employees (FTEs) assigned to ordering materials and services (Figure 1).

The data indicates that just over 36% of procurement FTEs work on this process. Over the last nine years, APQC has seen this percentage decrease among organizations taking its benchmarking survey, but the process still retains the largest share of FTEs within procurement. The fact that many procurement staff members are dedicated to completing what is largely a tactical activity that provides little strategic value to the organization is a motivation for finding ways to shift procurement staff to other processes.

Related to the amount of staff needed for ordering materials and services is the breakdown of the cost organizations incur for this activity (Exhibit 2). Nearly half of an organization’s cost for ordering materials and services goes toward personnel. By comparison, nearly 24% of the cost related to ordering materials and services goes toward overhead, and nearly 16% of the cost is devoted to outsourcing.

|

This complete article is available to subscribers

only. Click on Log In Now at the top of this article for full access. Or, Start your PLUS+ subscription for instant access. |

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

|

Download Article PDF |

When organizations think of the areas in their supply chains on which to focus to deliver cost reduction, they often select the procurement function. This is understandable because it is easy for an organization to incur extra costs in procurement due to inefficiencies in ordering and purchasing activities. In fact, when looking at its Open Standards Benchmarking data in procurement, APQC has found that organizations have the largest group of their procurement full-time equivalent employees (FTEs) assigned to ordering materials and services.

The data indicates that just over 36% of procurement FTEs work on this process. Over the last nine years, APQC has seen this percentage decrease among organizations taking its benchmarking survey, but the process still retains the largest share of FTEs within procurement. The fact that many procurement staff members are dedicated to completing what is largely a tactical activity that provides little strategic value to the organization is a motivation for finding ways to shift procurement staff to other processes.

Related to the amount of staff needed for ordering materials and services is the breakdown of the cost organizations incur for this activity (Exhibit 2). Nearly half of an organization's cost for ordering materials and services goes toward personnel. By comparison, nearly 24% of the cost related to ordering materials and services goes toward overhead, and nearly 16% of the cost is devoted to outsourcing.

|

SUBSCRIBERS: Click here to download PDF of the full article. |

SC

MR

Latest Supply Chain News

- AI, virtual reality is bringing experiential learning into the modern age

- Humanoid robots’ place in an intralogistics smart robot strategy

- Tips for CIOs to overcome technology talent acquisition troubles

- There is still work to do to achieve supply chain stability

- Blooming success: The vital role of S&OE in nurturing global supply chains

- More News

Latest Resources

Explore

Explore

Procurement & Sourcing News

- There is still work to do to achieve supply chain stability

- Blooming success: The vital role of S&OE in nurturing global supply chains

- How one small part held up shipments of thousands of autos

- Shining light on procurement’s dark purchases problem

- 40% of procurement leaders ignoring sustainability, study reveals

- ISM reports that services sector sees continued growth in March

- More Procurement & Sourcing

Latest Procurement & Sourcing Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks