Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

January-February 2012

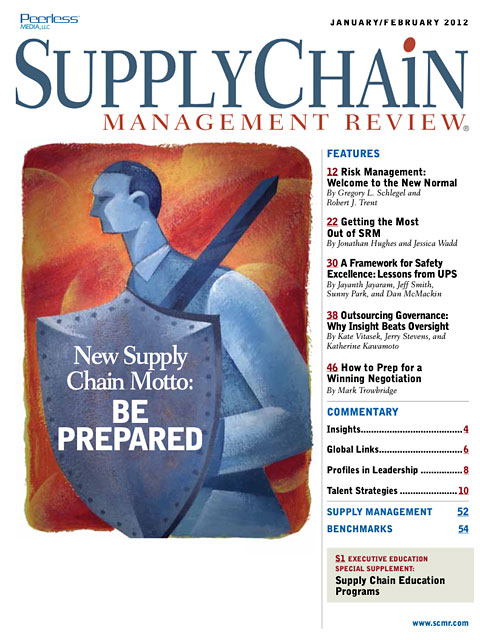

The potential risk of supply chain disruption has never been greater. In fact, it’s become the new normal, say authors and educators Robert Trent and Greg Schlegel. The problem for many companies is that they are ill prepared to handle a disruption should one occur. This article argues for a new set of risk management techniques in a world where heightened supply chain risk has become a fact of business life. Browse this issue archive.Need Help? Contact customer service 847-559-7581 More options

On a visit to UPS’s Worldport facility, which sits on 600 acres in Louisville, you would see why people call it one of the New Seven Wonders of the World. At the heart of the company’s global transportation network, this sophisticated mega hub sorts approximately 416,000 packages per hour over 115 miles of conveyor belts. On any typical day, the facility unloads 1.2 million packages from all around the world and then loads the sorted packages back onto more than 130 outbound flights within just five hours. UPS seamlessly choreographs all movements with an objective of minimizing delays, flaws, or disruptions. An internal research team estimated that the Worldport facility had one mis-sort for every 4,826 packages that flow through, which roughly translates to 99.9998 percent accuracy.

At Worldport and at other UPS facilities, every employee attends a pre-work communications meeting, which always concludes with a safety tip. Safety is a core value to UPS, and there is no room for unsafe work practices. Why does UPS commit to high safety standards? How does the company encourage the involvement of all employees in safety activities? This article seeks to answer these questions. We also offer some valuable “lessons learned” from the UPS experience for companies in other industries to consider. Finally, we outline the broader supply chain implications of a comprehensive safety initiative.

|

This complete article is available to subscribers

only. Click on Log In Now at the top of this article for full access. Or, Start your PLUS+ subscription for instant access. |

Not ready to subscribe, but need this article?

Buy the complete article now. Only $20.00. Instant PDF Download.

Access the complete issue of Supply Chain Management Review magazine featuring

this article including every word, chart and table exactly as it appeared in the magazine.

SC

MR

Sorry, but your login has failed. Please recheck your login information and resubmit. If your subscription has expired, renew here.

January-February 2012

The potential risk of supply chain disruption has never been greater. In fact, it’s become the new normal, say authors and educators Robert Trent and Greg Schlegel. The problem for many companies is that they are… Browse this issue archive. Download a PDF file of the January-February 2012 issue. |

Download Article PDF |

On a visit to UPS’s Worldport facility, which sits on 600 acres in Louisville, you would see why people call it one of the New Seven Wonders of the World. At the heart of the company’s global transportation network, this sophisticated mega hub sorts approximately 416,000 packages per hour over 115 miles of conveyor belts. On any typical day, the facility unloads 1.2 million packages from all around the world and then loads the sorted packages back onto more than 130 outbound flights within just five hours. UPS seamlessly choreographs all movements with an objective of minimizing delays, flaws, or disruptions. An internal research team estimated that the Worldport facility had one mis-sort for every 4,826 packages that flow through, which roughly translates to 99.9998 percent accuracy.

At Worldport and at other UPS facilities, every employee attends a pre-work communications meeting, which always concludes with a safety tip. Safety is a core value to UPS, and there is no room for unsafe work practices. Why does UPS commit to high safety standards? How does the company encourage the involvement of all employees in safety activities? This article seeks to answer these questions. We also offer some valuable “lessons learned” from the UPS experience for companies in other industries to consider. Finally, we outline the broader supply chain implications of a comprehensive safety initiative.

|

SUBSCRIBERS: Click here to download PDF of the full article. |

SC

MR

Latest Supply Chain News

- Few executives believe their supply chains can respond quickly to disruptions

- Technology’s role in mending supply chain fragility after recent disruptions

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- More News

Latest Podcast

Explore

Explore

Latest Supply Chain News

- Few executives believe their supply chains can respond quickly to disruptions

- Technology’s role in mending supply chain fragility after recent disruptions

- Tech investments bring revenue increases, survey finds

- Survey reveals strategies for addressing supply chain, logistics labor shortages

- Israel, Ukraine aid package to increase pressure on aerospace and defense supply chains

- How CPG brands can deliver on supplier diversity promises

- More latest news

Latest Resources

Subscribe

Supply Chain Management Review delivers the best industry content.

Editors’ Picks